An ultrasonic gas relative humidity detection method and device using sound velocity changes

A relative humidity and detection method technology, applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problems of reducing sensor sensitivity and measurement accuracy, and achieve convenient and fast detection, accurate measurement results, Measuring the effect of low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

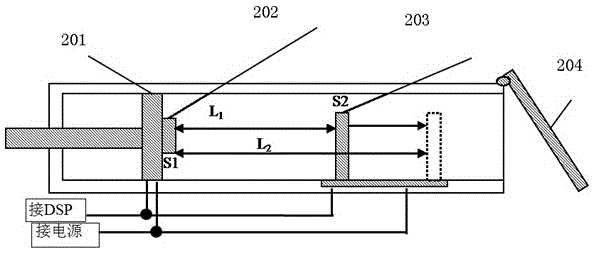

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be further described below in conjunction with examples, but the implementation and protection of the present invention are not limited thereto.

[0040] The principle utilized by the present invention is that the propagation speeds of sound waves in air with different humidity are different, and this difference is relatively obvious. In the case of the same temperature, the higher the relative humidity of the air, the lower the propagation speed of sound waves.

[0041] The speed of sound has nothing to do with the nature of the sound source, but only with the elasticity, density and temperature of the medium. According to the theory of sound wave propagation, the speed of sound wave propagation in gas is:

[0042] V = K ρ - - - ( 1 )

[0043] In the above formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com