Axisymmetric curved surface rotary variable displacement pump

An axisymmetric, variable displacement pump technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, rotary piston machines, etc., which can solve local resistance increase, hard material wear, reduce pump Effective volume and other issues, to achieve the effect of improving the ability to resist fluid pressure, reducing strength, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

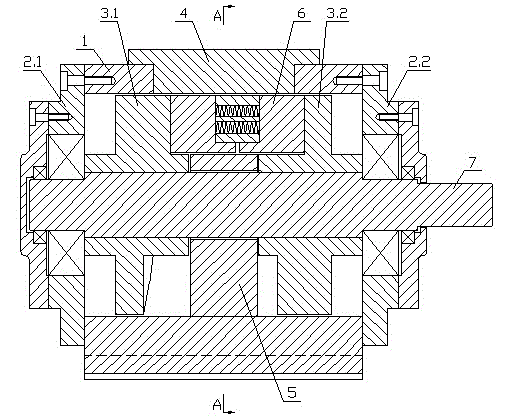

[0031] Embodiment 1: see image 3 , the axisymmetric curved surface rotary variable displacement pump of the present invention comprises a pump casing 1 with a cylindrical inner cavity and assembled pump covers 2.1 and 2.2 supporting the rotating shaft at both ends, and a fixed partition plate 5 in the axial middle of the pump chamber divides the pump into The left and right chambers coincide with the axis of the pump chamber and pass through the rotating shaft 7 of the partition plate 5. The pump casing 1 has a liquid inlet 9 and a liquid outlet 8 opposite to the partition plate 5. The two sides of the partition plate 5 are in rotation with the surrounding surface of the pump chamber 1. The curved surfaces are opposite and staggered by 180 degrees. The axisymmetric curved surface turntables 3.1 and 3.2 are fixed on the rotating shaft. There is an axial chute in the middle of the liquid inlet and outlet (9, 8) of the separation disk 5. The interpolation can slide back and forth...

Embodiment 2

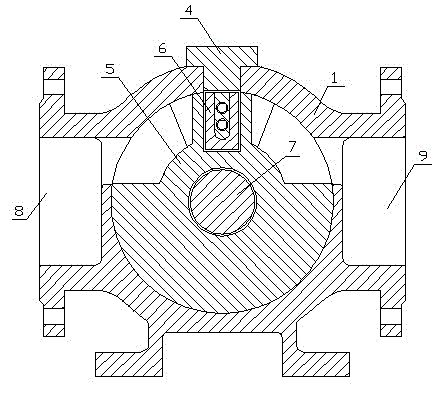

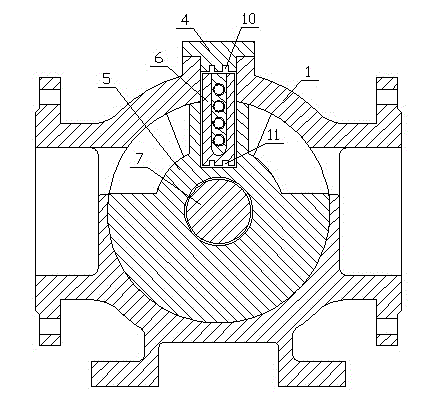

[0032] Example 2: see Figure 4 , 5 , 6, 7, as shown above, there is a blind hole in the center of the curved surface turntable 3.1 and 3.2, and there are axial extensions 5.1 and 5.2 extending into the blind holes of the curved turntable in the middle of the two sides of the partition plate 5, and the axial extension ( 5.1, 5.2) The length is longer than the sliding baffle extending out from the separation disc 5 strokes, and the axial extension section (5.1, 5.2) is provided with an axial chute 5.3 at the same position as the separation disc 5 axial chute, and the widened upper and lower ends are respectively inserted into the pump 5.3 in the shell through groove and the axial chute of the extension of the partition plate.

Embodiment 3

[0033] Embodiment 3: see Figure 8 , as mentioned above, wherein the negative pressure side of the sliding baffle and the left and right sliding baffle guide blocks have axial grooves 12 and 13 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com