Coal-bed gas multi-branch horizontal-well system

A multi-branch and horizontal well technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as wellbore wall collapse and achieve the effect of ensuring clean, efficient production and improving drainage and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A coalbed methane multi-lateral horizontal well system A is further described in detail.

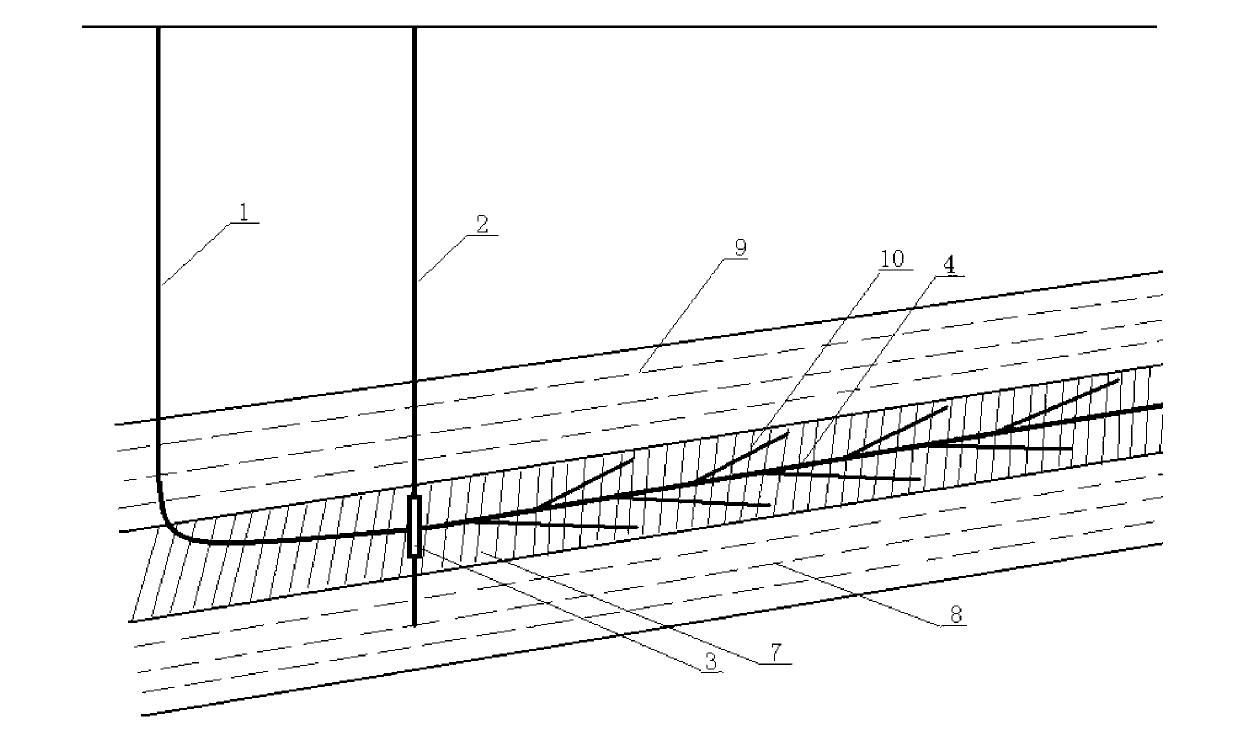

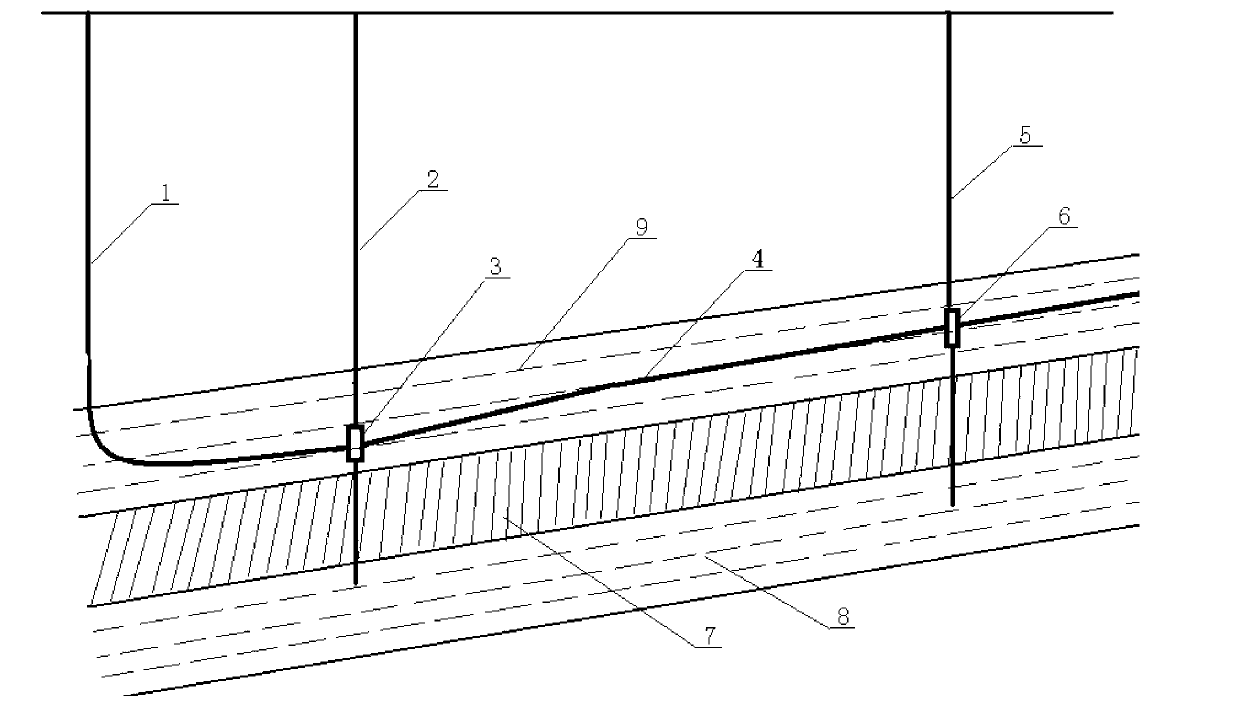

[0039] refer to figure 2 . CBM multi-branch horizontal well system A (the main branch 4 of the multi-branch horizontal well 1 is on the coal seam roof 9). Coalbed methane multi-branch horizontal well system A is located in a sedimentary basin. The coal seam in this basin is 785m deep, 4.0m thick, and 3° in dip. The top of the coal seam is dark gray mudstone, 4° in dip, and 8.0m thick.

[0040] refer to figure 2 , Figure 5 . The coalbed methane multi-branch horizontal well system A is composed of a multi-branch horizontal well 1, a first drainage vertical well 2, and a second drainage vertical well 5. The horizontal section of the multi-branch horizontal well 1 consists of a main branch 4, branches 10 and The vein branch 11 is composed; the first row of mining vertical wells 2 has the first row of mining vertical well caves 3, and the second row of mining vert...

Embodiment 2

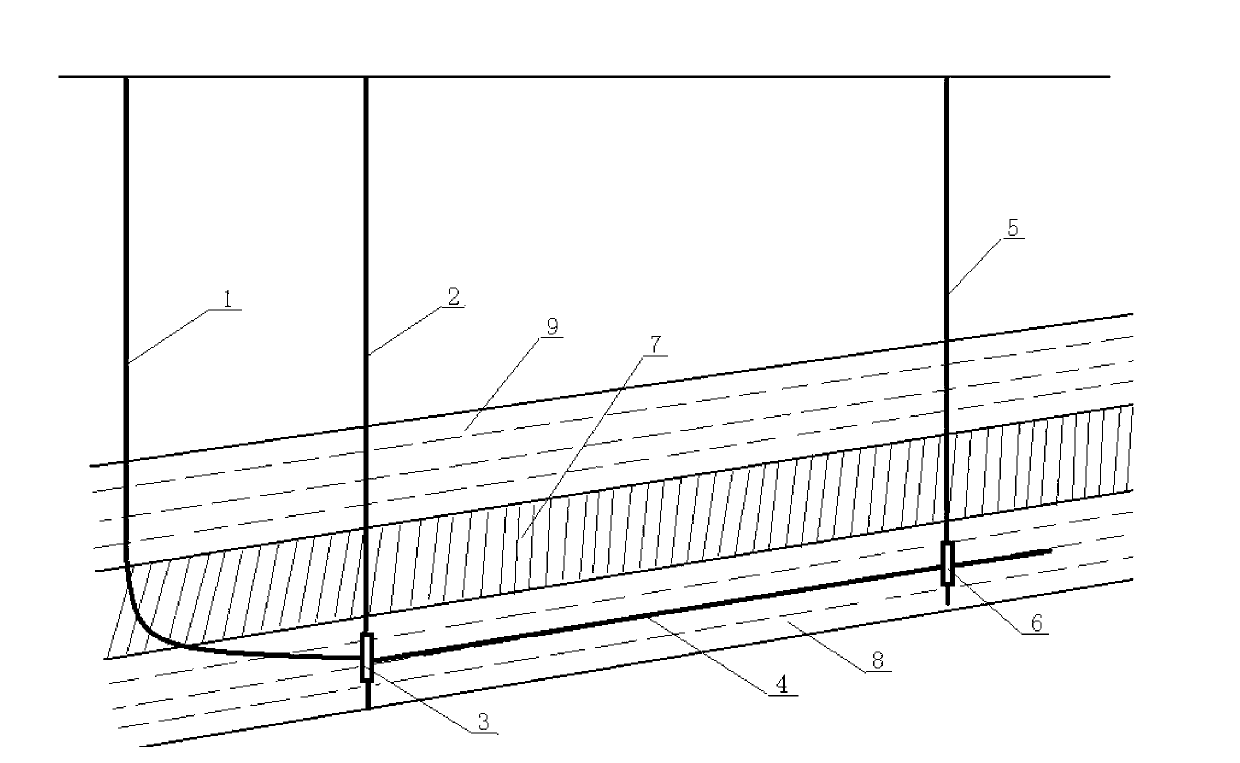

[0051] Example 2: Coalbed methane multi-branch horizontal well system B (the main branch 4 of the multi-branch horizontal well 1 is on the coal seam floor 8). Coalbed methane multi-branch horizontal well system B is located in a sedimentary basin, where the coal seam is 785m deep, the coal seam 7 is 4.0m thick, and the coal seam dip is 3°. The bottom of the coal seam is dark gray mudstone, the formation dip is 4°, and the thickness is 8.0m.

[0052] refer to image 3 , Image 6 . The difference from Embodiment 1 is: the main branch 4 of the multi-branch horizontal well 1 of the system B is on the coal seam floor 8 .

[0053] System B is composed of a multi-branch horizontal well 1, a first vertical production well 2 and a second vertical production well 5, and the horizontal section of the multi-branch horizontal well 1 is composed of a main branch 4, branches 10 and vein branches 11; A row of mining vertical wells 2 has the first row of mining vertical wells 3, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com