A protective device for polysilicon ingot crucible

A protection device, polysilicon technology, applied in the direction of polycrystalline material growth, crystal growth, silicon compounds, etc., can solve the problems of polycrystalline silicon quality influence, no cover plate, impurities entering silicon melt, etc., to improve the utilization rate and slicing efficiency. rate, reduce precipitation and agglomeration, improve the effect of gas circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

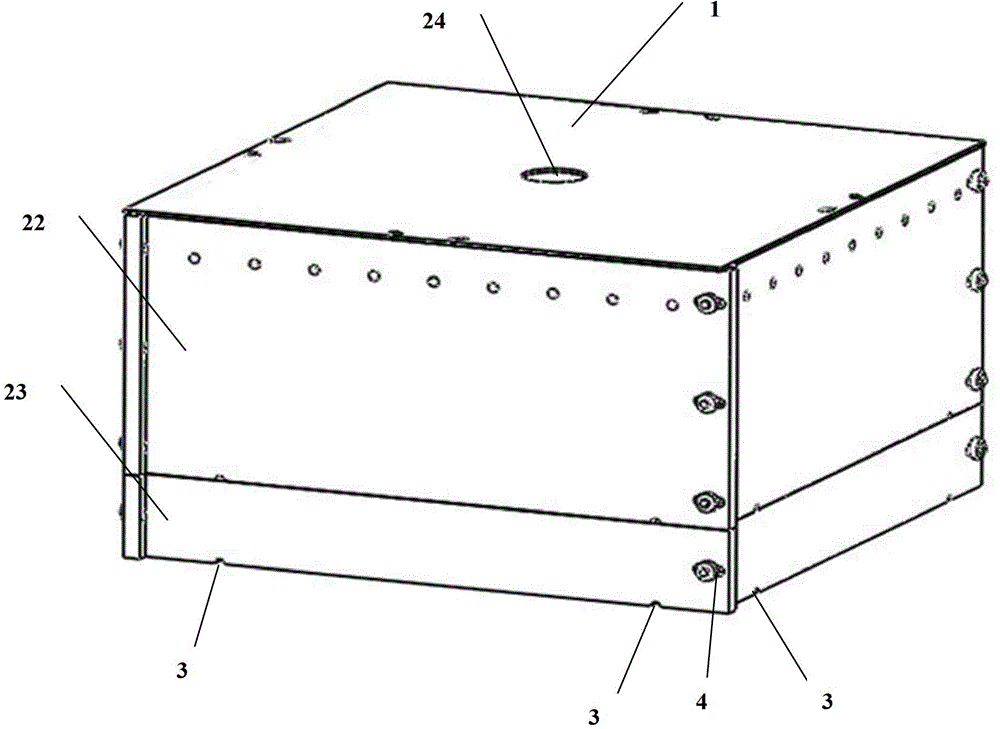

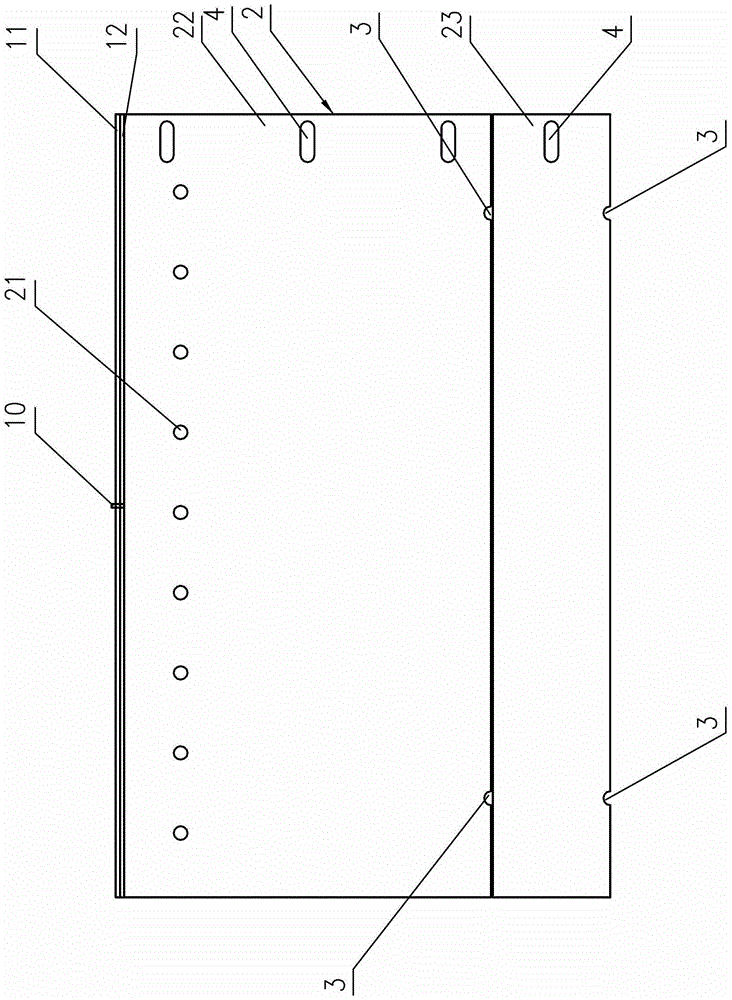

[0033] Such as Figure 1~3As shown, it is a protective device for a polysilicon ingot crucible according to the present invention, which includes a guard plate formed by connecting vertical plates in twos, and a cover plate 1 and a bottom plate respectively arranged on the guard plate and the lower end (not shown in the figure) , the cover plate 1 is fastened to the opening of the upper end of the guard plate 2 to form an inner space for placing the polysilicon ingot crucible, and the cover plate 1 is composed of a common C / C plate 11 and a metal plate combined on the lower surface of the C / C plate 11 12 components, wherein the melting point of the metal plate 12 is greater than 1800K; the upper part of the guard plate 2 has an air outlet 21 and the air outlet 21 corresponds to the top of the polysilicon ingot crucible, and the cover plate is opened through the C / C plate 11 and the metal plate 12 The air inlet 24 for feeding argon into the inner space is used to ventilate the ...

Embodiment 2

[0041] The guard plate assembly of this embodiment has three layers (not shown in the figure), that is, the guard plate is composed of a lower layer, a middle layer, and an upper layer guard plate assembly. There are four board bodies in the upper and lower layer guard plate assemblies. There are two plate bodies in the guard plate assembly; two overflow holes are arranged on the lower edge of each plate body of the lower guard plate assembly. The upper guard plate assembly is provided with an air outlet, and the air outlet is a circular hole. In this embodiment, the center of the air outlet is 40 mm from the upper edge of the upper guard plate assembly. The distance between adjacent air outlets is 62mm, and the diameter of the air outlets is 16mm.

[0042] In the three-layer guard plate assembly, the board heights of the adjacent two-layer guard board assemblies are different, and the higher part of the higher board body relative to the other board bodies in this guard board ...

Embodiment 3

[0046] The shield assembly of the present embodiment has four layers, and the shield is composed of the superposition of the lower layer, the middle layer, the upper middle layer and the upper layer board assembly, and the number of board bodies in each layer of shield assembly is four; Three overflow holes are arranged on the lower edge of each plate body. The upper guard plate assembly is provided with an air outlet, and the air outlet is a circular hole. In this embodiment, the center of the air outlet is 80 mm from the upper edge of the upper guard plate assembly, and each plate body of the upper guard plate assembly is equidistantly provided with 14 Air outlets, the distance between adjacent air outlets is 54mm, and the diameter of the air outlets is 20mm.

[0047] The height of each plate body in the lower guard plate assembly is 80mm, and one side of each plate body is provided with a screw hole, and the end face of one side of the adjacent plate body is also provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com