Protection device for nickel/chromium composite plating

A protective device and a composite electroplating technology are applied to nickel-chromium composite electroplating protective devices and nickel-chromium composite electroplating protection for excavator hydraulic cylinder piston rods. It can solve the problems that the bolt fixing structure is not easy to be firmly clamped, easy to skew or fall off, and has poor reusability, and achieves the effects of good protection effect, reduced labor intensity, and convenient and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

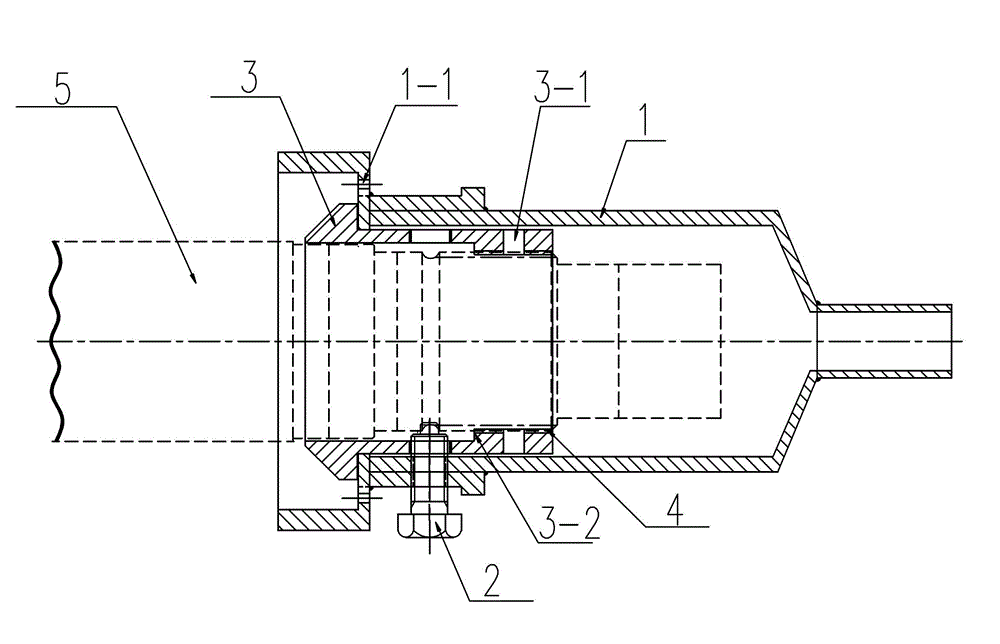

[0011] Such as figure 1 In the shown embodiment, the nickel-chromium composite electroplating protective device comprises a protective outer cover 1, a protective inner cover 3 with an end cap installed at one end of the protective outer cover 1, the outer diameter of the protective inner cover 3 cooperates with the inner diameter of the protective outer cover 1, and the inner diameter matches the oil cylinder. Cooperate with piston rod 5; the protective jacket is a step pipe, and the jacket drain hole 1-1 is arranged on the step at one end of the protective jacket; the inner jacket drain hole 3-1 and the drain groove 3-2 are arranged on the protective inner jacket , the protective inner sleeve 3 and the protective outer sleeve 1 are combined together by bolts 2; there is an inner sleeve thread 4 on the inner wall of the protective inner sleeve, and the entire protection device is fixed on the cylinder piston rod through the inner sleeve thread 4 of the protective inner sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com