Thermal treatment process of Invar alloy

A heat treatment furnace and process technology, applied in the field of heat treatment process of Invar alloy, can solve the problems such as not obvious, achieve the effect of improving the effect, reasonable treatment process and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

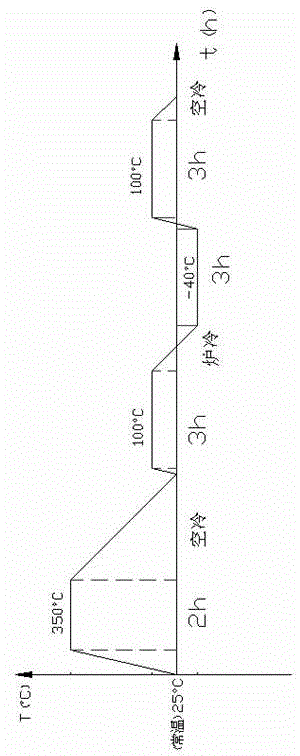

[0018] The principle diagram of the present invention is as figure 1 As shown, the heat treatment process of the Invar alloy of the present invention adopts a gradient cyclic annealing stress relief process, which specifically includes the following steps:

[0019] 1) Put the workpiece into a heat treatment furnace at 250°C to 400°C for 1.5 hours to 2.5 hours;

[0020] 2) Take the workpiece out of the heat treatment furnace and cool it to room temperature under air;

[0021] 3) Place the workpiece in a heat treatment furnace at 80°C to 120°C for 1.5 hours to 2.5 hours;

[0022] 4) Then place the workpiece in a cold furnace at -30°C to -50°C for 1.5 hours to 2.5 hours;

[0023] 5) Place the workpiece in a heat treatment furnace at 80°C to 120°C for 1.5 hours to 2.5 hours;

[0024] 6) Take the workpiece out of the heat treatment furnace and cool it to room temperature under air.

[0025] In this embodiment, the above step 1) put the workpiece into a heat treatment furnace at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com