AlOOH catalyst for polyester polycondensation and preparation method thereof

A technology of catalyst and polyester is applied in the field of catalyst and its preparation, and achieves the effects of abundant raw material sources, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

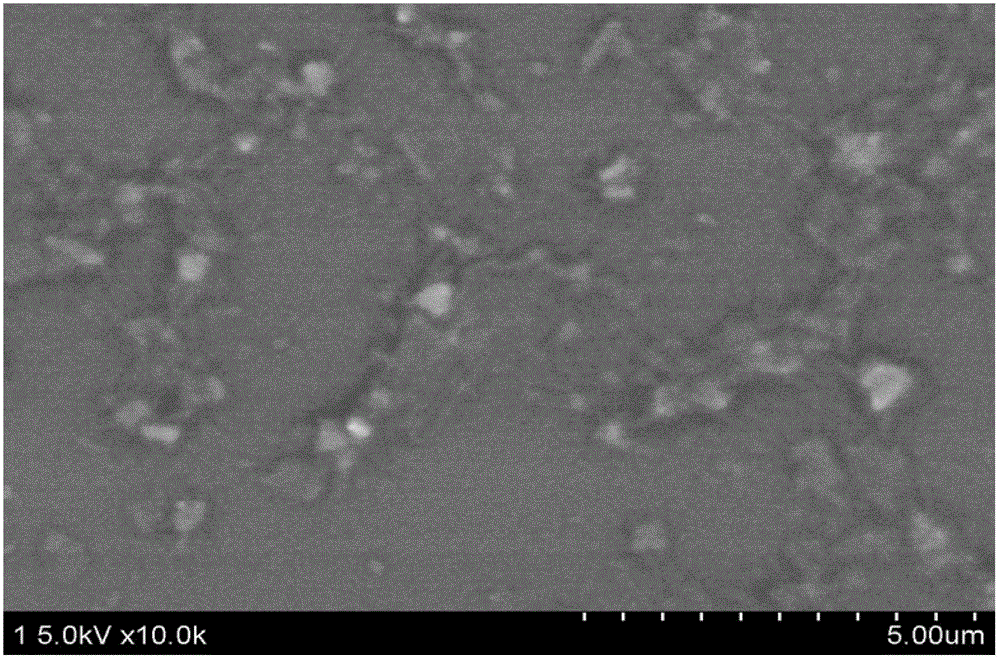

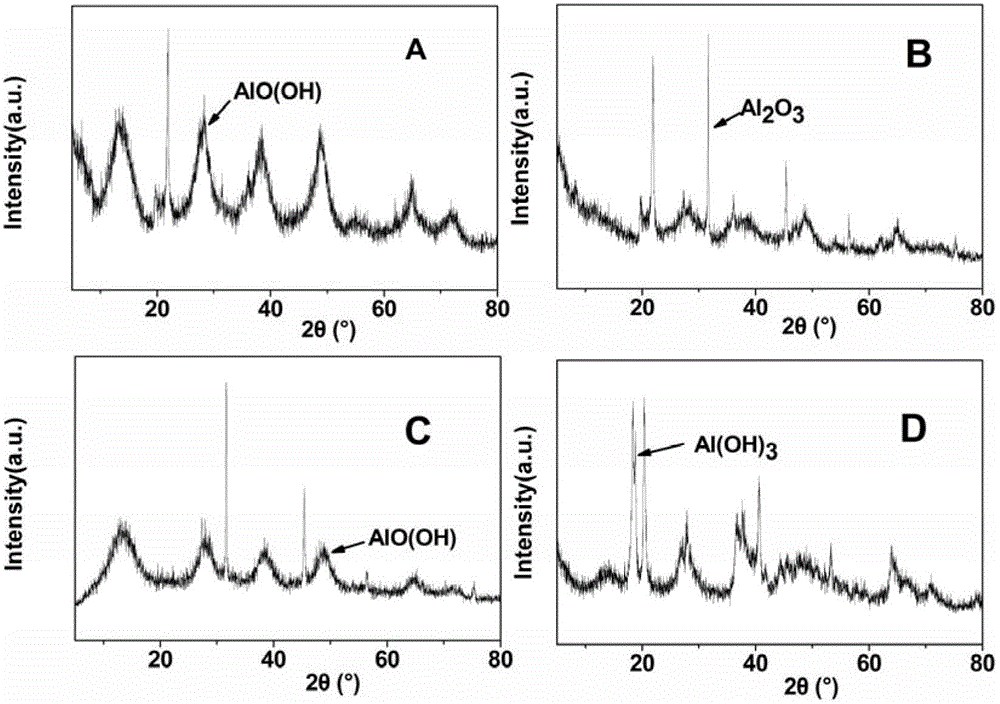

Image

Examples

Embodiment 1

[0026] Pass the untreated attapulgite through a 200-mesh sieve to remove impurities, weigh 15g, add deionized water to make a suspension with a mass fraction of about 4%, stir for 1 hour, then add 150ml of hydrogen peroxide, and After standing for 30 minutes, the supernatant suspension was decanted to remove the residual impurities in the bottom layer.

[0027] 150 ml of 0.5 mol / L hydrochloric acid was added to the above-mentioned purified suspension, stirred for 1 hour, then sonicated for 30 minutes, and then allowed to stand for 30 minutes. The upper layer suspension was decanted, and after centrifugation, the obtained solid was washed 3 times with deionized water, and finally the washed attapulgite was dried and ground for later use.

[0028] Add 0.2mol / L NaAlO in the flask 2 Solution 250ml, add 0.2g attapulgite, first ultrasonic 30MIN, after fully dispersed, drop 0.5mol / L HCL solution in the flask until the pH value is 7±0.1, and white precipitate appears in the reaction ...

Embodiment 2

[0031] Pass the untreated attapulgite through a 200-mesh sieve to remove impurities, weigh 15g, add deionized water to make a suspension with a mass fraction of about 4%, stir for 1 hour, then add 150ml of hydrogen peroxide, and After standing for 30 minutes, the supernatant suspension was decanted to remove the residual impurities in the bottom layer.

[0032] 150 ml of 0.5 mol / L hydrochloric acid was added to the above-mentioned purified suspension, stirred for 1 hour, then sonicated for 30 minutes, and then allowed to stand for 30 minutes. The upper layer suspension was decanted, and after centrifugation, the obtained solid was washed 3 times with deionized water, and finally the washed attapulgite was dried and ground for later use.

[0033] Add 0.2mol / L NaAlO in the flask 2 Solution 250ml, add 1g of attapulgite, first ultrasonic 30MIN, after fully dispersed, drop 0.5mol / L HCL solution in the flask until the pH value is 7±0.1, and white precipitate appears in the reaction...

Embodiment 3

[0036] Pass the untreated attapulgite through a 200-mesh sieve to remove impurities, weigh 15g, add deionized water to make a suspension with a mass fraction of about 4%, stir for 1 hour, then add 150ml of hydrogen peroxide, and After standing for 30 minutes, the supernatant suspension was decanted to remove the residual impurities in the bottom layer.

[0037] 150 ml of 0.5 mol / L hydrochloric acid was added to the above-mentioned purified suspension, stirred for 1 hour, then sonicated for 30 minutes, and then allowed to stand for 30 minutes. The upper layer suspension was decanted, and after centrifugation, the obtained solid was washed 3 times with deionized water, and finally the washed attapulgite was dried and ground for later use.

[0038] Add 0.2mol / L NaAlO in the flask 2Solution 250ml, add 0.1g attapulgite, first ultrasonic 30MIN, after fully dispersed, drop 0.5mol / L HCL solution in the flask until the pH value is 7±0.1, and white precipitate appears in the reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com