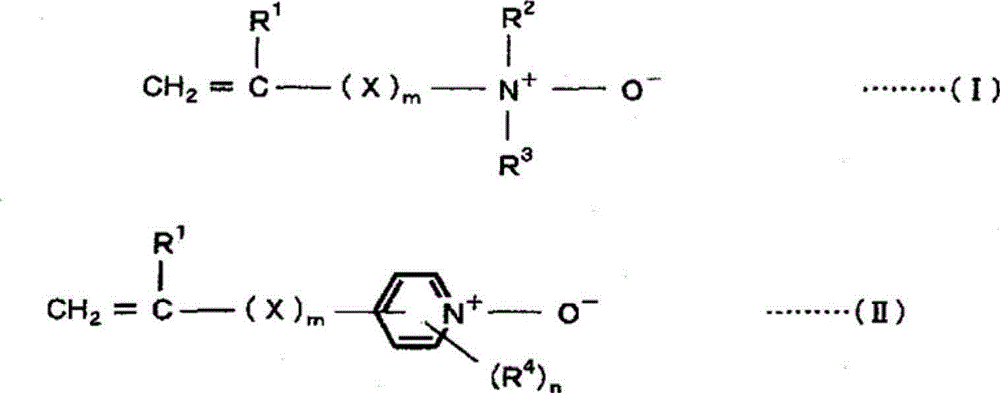

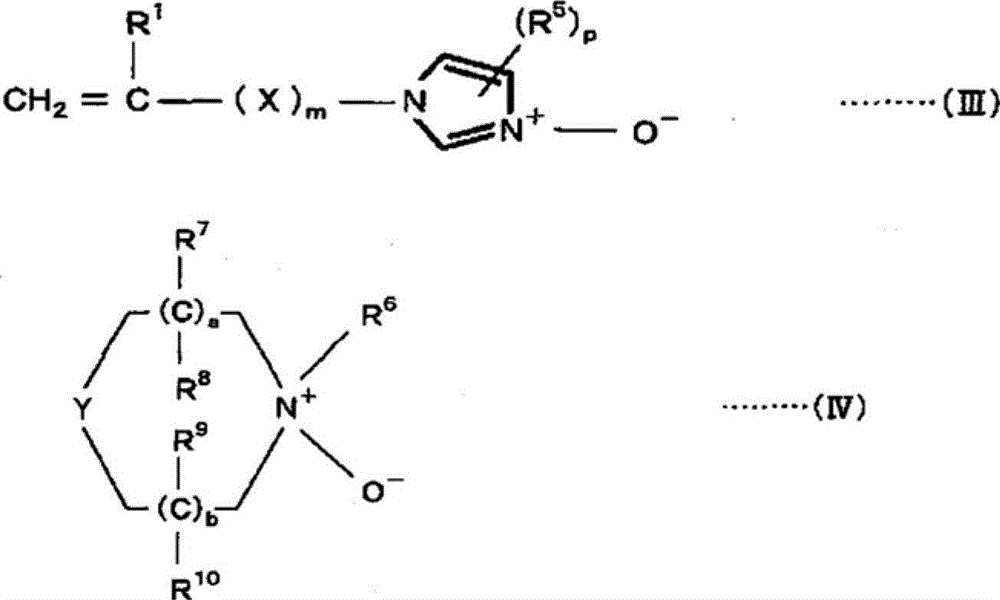

Resin solution containing amine oxide group and resin composition for hair cosmetic material using the same

A technology for hair cosmetic and resin composition, which can be applied in the directions of cosmetics, cosmetic preparations, hair care, etc., and can solve problems such as quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] When the polymerization inhibitor content of the amine oxide group-containing resin solution used in the preparation of the resin composition for hair cosmetics exceeds 800 ppm of the content of the amine oxide group-containing resin, there is a problem of coloring, which is not ideal as a resin composition for hair cosmetics. The less the polymerization inhibitor content in the amine oxide-containing resin solution, the better, more preferably below 750ppm of the amine oxide-containing resin, more preferably below 600pprn, even more preferably below 500ppm, even more preferably below 400ppm, Particularly preferably, it is 250 ppm or less.

[0074] In addition, the amine oxide group-containing resin solution referred to here is an amine oxide group-containing resin solution used as a raw material for the production of a resin composition for hair cosmetics supplied from the production process of the amine oxide group-containing resin as described above. Amino resin, wat...

Embodiment

[0217] The following production examples and examples are given to describe the present invention more specifically.

[0218] In addition, hereinafter, "part" means "weight part", and "%" and "ppm" mean "weight%" and "weight ppm", respectively.

[0219] In addition, all the raw material monomers used were manufactured by Mitsubishi Rayon Co., Ltd., and the concentration of MEHQ with respect to the weight of each monomer is shown below.

[0220] Dimethylaminoethyl methacrylate: 2000ppm

[0221] Lauryl methacrylate: 1000ppm

[0222] Tert-butyl methacrylate: 200ppm

[0223] In addition, the above-mentioned raw material monomers, the MEHQ concentration of the produced resin solution, etc. were analyzed and obtained by the following method.

[0224]

[0225] Gas chromatograph: "HP6850 series GC system" manufactured by Hewlett-Packard Co., Ltd. was used for measurement under the following conditions and specifications.

[0226] Column: "HP-1" manufactured by Hewlett Packard

...

manufacture example 1

[0232] Production Example 1: Production of Resin Solution P-1

[0233] Add 50 parts of dimethylaminoethyl methacrylate, 25 parts of dodecyl methacrylate, 25 parts of 200 parts of tert-butyl methacrylate and 200 parts of absolute ethanol, add 0.2 parts of dimethyl 2,2'-azobisisobutyrate, heat to 80°C under nitrogen flow while stirring, and react for 8 hours to obtain copolymerization substance solution. The copolymer had a weight average molecular weight (in terms of polystyrene) of 100,000 as determined by GPC (gel permeation chromatography) analysis using polystyrene as a standard substance.

[0234] Then, using a dropping funnel, dropwise add hydrogen peroxide (using 34% hydrogen peroxide) equimolar to the added dimethylaminoethyl methacrylate in the solution obtained above in 1 hour, and then, under nitrogen flow, , Heated to reflux at the boiling point for 12 hours to carry out the oxidation reaction of dimethylamino. In addition, the terminal point of the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com