Simultaneous desulfurization and denitration catalyst and preparation method thereof

A desulfurization and denitrification, catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of large catalyst bed resistance, low mechanical strength, uneven pressure, etc., and achieve simple preparation and regeneration methods , High mechanical strength, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

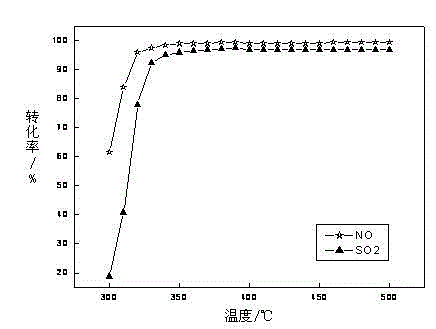

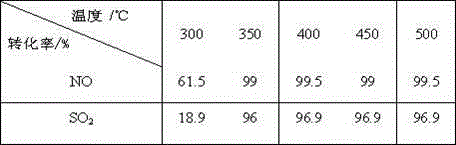

Image

Examples

Embodiment 1

[0015] Example 1 Simultaneous desulfurization and denitrification catalyst Nd 2 o 3 - Preparation of CoO / AC:

[0016] Weigh 11.5gNd(NO 3 ) 3 ·5H 2 0 and 11.4gCo (NO 3 ) 2 ·6H 2 0 was dissolved in 80ml of deionized water and heated to 75°C, then 10g of polyvinyl alcohol with a molecular weight of 80,000 was added, stirred until the polyvinyl alcohol was completely dissolved, then 50g of activated carbon powder was put into the above viscous mixed solution and stirred evenly, and squeezed After forming the strips, dry them at 80°C for 6 hours, then dry them at 150°C, and finally bake them at 200°C for 2 hours and then at 900°C for 4 hours under the protection of nitrogen to obtain a columnar simultaneous desulfurization and denitrification catalyst with a diameter of 2 cm and a length of 2 to 5 cm. 10%Nd 2 o 3 -5%CoO / AC, namely AC, Nd 2 o 3 The weight parts with CoO are 85, 10 and 5 respectively, and the specific surface area of the catalyst is 361.9m 2 g -1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com