Control and drive circuit and method

A driving circuit and driving method technology, applied in the direction of electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., can solve the problems of difficult transmission of duty ratio signals, increased circuit volume and cost, etc., to improve system efficiency, Effect of reducing cost and volume, suppressing common mode interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

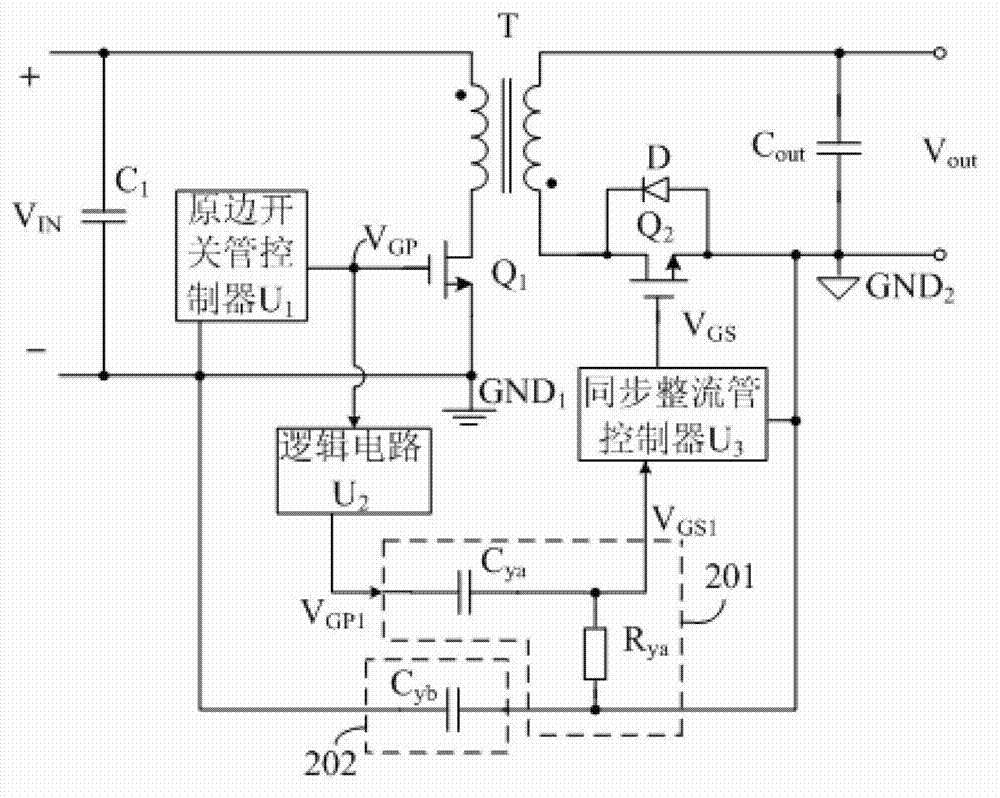

Embodiment 1

[0043] Such as Figure 2A The illustrated embodiment is a flyback synchronous rectification switching power supply. The flyback synchronous rectification switching power supply includes a power stage circuit and a driving circuit for converting the DC voltage V IN converted to the output voltage V out , wherein the power stage circuit includes a filter capacitor C 1 , transformer T, primary side switch tube Q 1 , Synchronous rectifier tube Q 2 and output filter capacitor C out ; The drive circuit includes the primary switch tube controller U 1 , logic circuit U 2 , conversion circuit 201 and synchronous rectifier controller U 3 . The primary switch tube controller U 1 Used to generate the control signal V of the primary switch tube GP to control the primary switch Q 1 is turned on and off, and its first output end is connected to the primary switch tube Q 1 The control terminal and the logic circuit U 2 The input terminal; the logic circuit U 2 used to receive th...

Embodiment 2

[0056] Such as image 3 The example shown is in the Figure 2A An improved flyback synchronous rectification switching power supply based on the circuit. and Figure 2A The difference of the flyback synchronous rectification switching power supply shown is that in order to protect the primary switching tube controller U 1 and the synchronous rectifier controller U 3 , this embodiment adds a first clamping circuit 301 and a second clamping circuit 302 . The first clamping circuit 301 includes a first diode D 1 , the second diode D 2 , the first clamping voltage V CLP1 and the second clamping voltage V CLP2 , the first diode D 1 The cathode is connected to the first clamping voltage V CLP1 , anode connected to the second diode D 2 The cathode of which is connected to the input end of the conversion circuit 201, and the second diode D 2 The anode is connected to the second clamping voltage V CLP2 ; The second clamping circuit 302 includes a third diode D 3 , the four...

Embodiment 3

[0064] Such as Figure 4 Shown is the forward synchronous rectification switching power supply in the third embodiment of the present invention. The forward synchronous rectification switching power supply includes a power stage circuit and a drive circuit, wherein the power stage circuit includes a filter capacitor C 1 , transformer T, primary side switch tube Q 1 , Synchronous rectifier tube Q 2 , Synchronous rectifier tube Q 3 and output filter capacitor C out ; The drive circuit includes the primary switch tube controller U 1 , logic circuit U 2 , conversion circuit 201 and synchronous rectifier controller U 3 . and Figure 2A The difference between the flyback synchronous rectification switching power supply in the first embodiment shown is that in this embodiment, the transformer T is connected to the terminal of the same name, and the synchronous freewheeling tube Q 3 with the output filter capacitor C out connected in parallel, the synchronous rectifier contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com