Capacitive touch screen having single-layer bridge-striding structure

A capacitive touch screen, single-layer multi-point technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems affecting the reliability of the touch screen, shortening the life of the touch screen, and damaging the touch screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

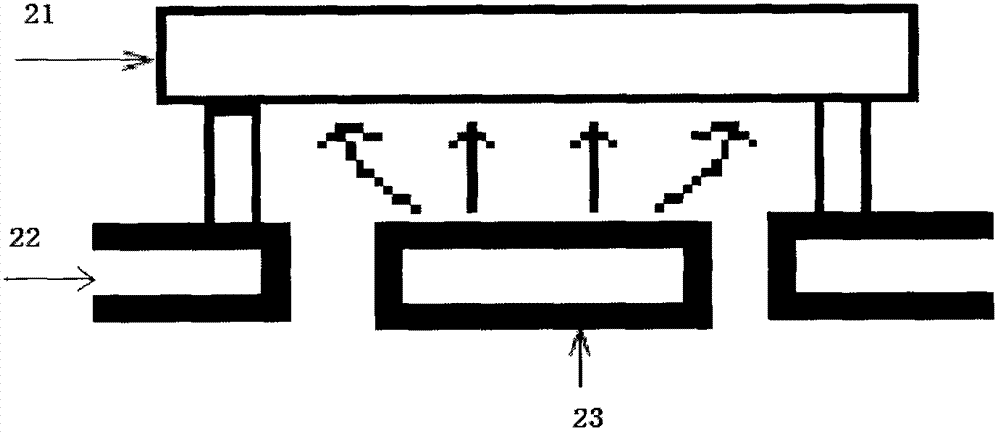

[0017] figure 2 It is a cross-sectional view of the cross-bridge part of the mutual-capacitance single-layer cross-bridge capacitive touch screen of the present application. 21 is a bridge metal connection, 22 is a sensing electrode, and 23 is a driving electrode. The sensing electrodes and the bridge metal wires are connected through holes, and the sensing electrodes are connected to each other through the bridge metals and the holes; the driving electrodes and the bridge metals are separated by insulating dielectrics.

[0018] The sensing capacitance of a single-layer bridge structure capacitive touch screen consists of the following two parts: the overlap capacitance between the bridge metal and the underlying driving electrodes, and the sidewall capacitance between the sensing electrodes and the driving electrodes.

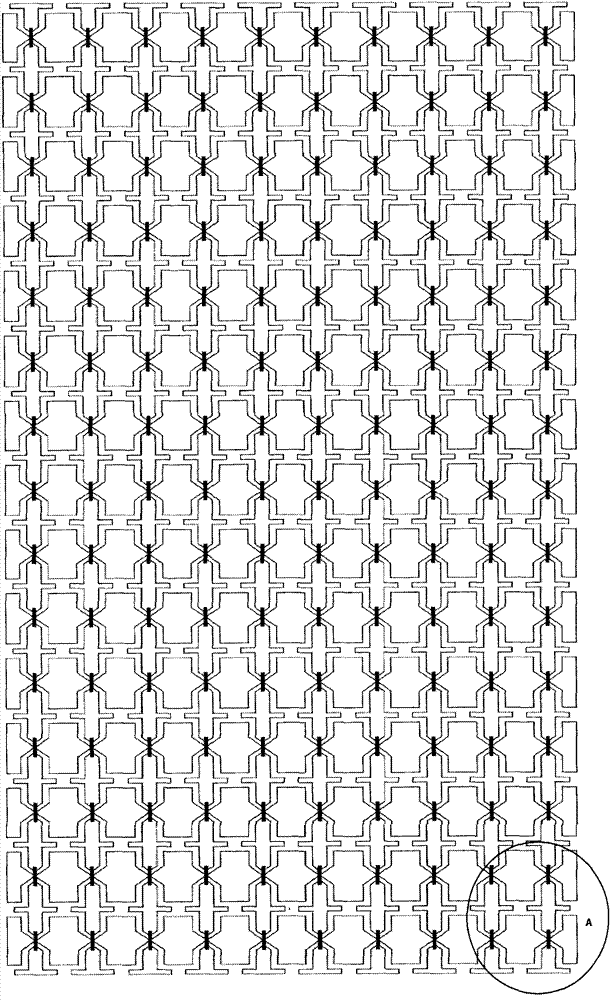

[0019] image 3 It is a schematic diagram of the overall structure of the single-layer cross-bridge capacitive touch screen of the present application. Fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com