High-sensitivity micro-nano fiber compound type microcavity biochemical sensor and manufacture method thereof

A biochemical sensor and micro-nano optical fiber technology, applied in the field of optical fiber devices, can solve the problems of slow response speed and low sensitivity, and achieve the effects of fast response speed, wide application prospects and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] see figure 1 , the high-sensitivity micro-nano optical fiber composite microcavity biochemical sensor consists of a micro-nano optical fiber (4) and a first optical fiber internal reflection mirror (1), a second optical fiber internal reflection mirror (2), a micro-nano optical fiber (4), and a micro-nano optical fiber (4). An optical fiber F-P cavity (3) and a junction-type micro-nano optical fiber ring cavity (5) are formed. The micro-nano optical fiber (4) is made by flame processing a single-mode optical fiber, and the first optical fiber internal reflection mirror (1) and the second optical fiber internal reflection mirror (2) are respectively processed by femtosecond pulsed laser along the micro-nano optical fiber ( 4) The radial direction of the inner fiber core changes the reflective surface formed by the refractive index of the fiber. Then tie a knot between the two mirrors, and finally make a micro-nano-fiber composite microcavity composed of a micro-nano fi...

Embodiment 2

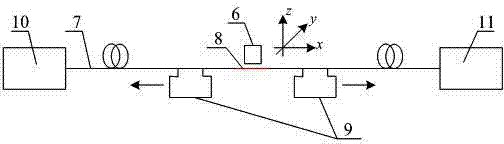

[0024] see figure 2 , the manufacturing method of the high-sensitivity micro-nano fiber composite microcavity biochemical sensor is used to make the micro-nano fiber according to the first embodiment. Use oxyhydrogen flame (6) as heat source to a section of 2 meters long A 0.2-meter single-mode optical fiber (7) is fused to make a micro-nano optical fiber: strip a length of 3 cm in the middle of the single-mode optical fiber 0.3 cm coating layer, and wipe the bare fiber part (8) with alcohol, place it on the fiber holder (9) with a distance of 5 cm, connect one end of the pigtail to the broadband light source (10), and connect the other end to the optical power meter (11), used to monitor the loss change of the single-mode fiber during the melting process. Through optimal setting of parameters such as the hydrogen flow rate of the heat source and the flame temperature, it can be ensured that the prepared micro-nano optical fiber (12) has good uniformity.

Embodiment 3

[0026] see image 3 , the manufacturing method of the high-sensitivity micro-nano-fiber composite microcavity biochemical sensor is used to make the F-P cavity written inside the micro-nano fiber by femtosecond laser according to the first embodiment. The prepared micro-nano fiber (12) is placed on the three-dimensional mobile platform (13), so that the axis of the micro-nano fiber (12) is perpendicular to the transmission direction of the femtosecond pulsed laser beam (14); the femtosecond pulsed laser (15) passes through The objective lens (16) of the microscope is focused on the center of the waist of the fiber fusion cone, and the three-dimensional mobile platform moves along the transmission direction of the femtosecond pulse laser, so that the focal point of the femtosecond pulse laser scans the waist of the fiber fusion cone along the radial direction of the optical fiber to reach the femtosecond pulse laser. The second laser writing area covers the fiber core of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com