Composite end enclosure and processing process

A technology of composite materials and processing technology, which is applied in the field of central air conditioning, can solve the problems of low pressure resistance, unstable quality, and poor sealing effect, and achieve the effects of saving metal materials, simplifying processing technology, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

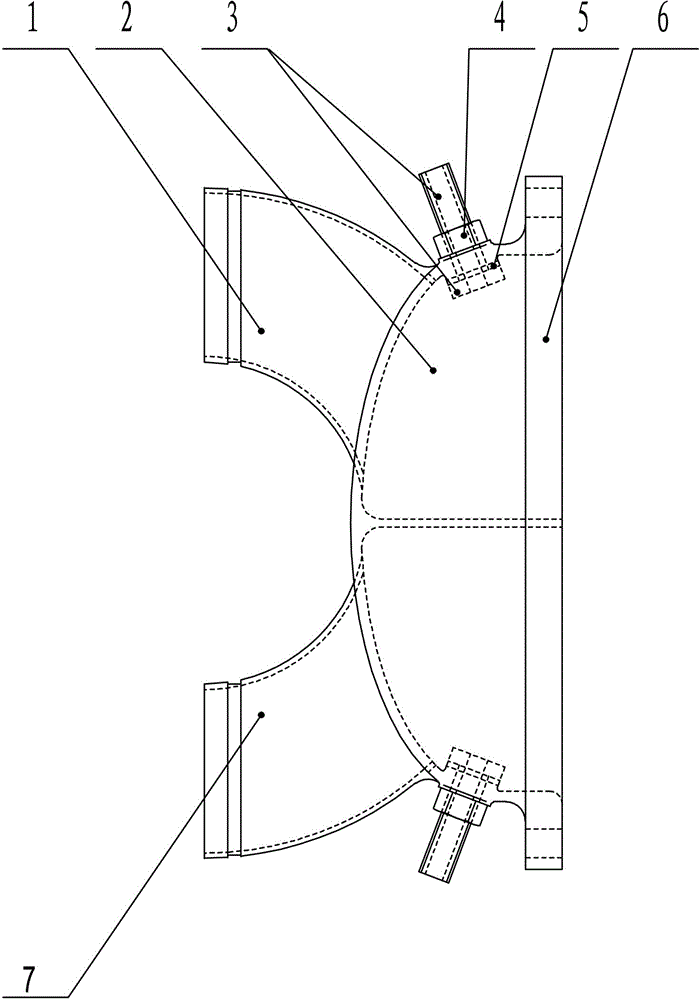

Image

Examples

Embodiment 1

[0022] As shown in the figure: the main body of the head 2 is set on the flange of the container, the valve seat 3 and the rubber gasket 5 are set on the main body of the head 2, the main body of the head 2 and the valve seat 3 are fastened with lock nuts, and the main body of the head 2 is The water inlet and outlet pipes 7 and 1 are provided; the water inlet and outlet pipes 7 and 1 are of semicircular clamp structure, forming an integrated composite material head. The processing method is to use the resin transfer molding process to directly form the inlet / outlet water connection, the head, and the flange of the container at one time; the installation position and structure of the valve seat are changed on the equipment, and the inlet / outlet water pipe is changed from a flange connection to a semicircle card. Hoop connection structure. Its specific processing steps are as follows:

[0023] A. Mold preparation: measure the size of the mold and check whether there is deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com