Novel precise and quantitative electrical oil gun

A quantitative type, oil gun technology, applied in the direction of quantitative devices, engine components, engine lubrication, etc., can solve the problems of equipment pollution, reduced lubrication effect, and many equipment lubrication failures, so as to prevent the occurrence of equipment mechanical accidents and reduce equipment Downtime and the effect of improving equipment productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

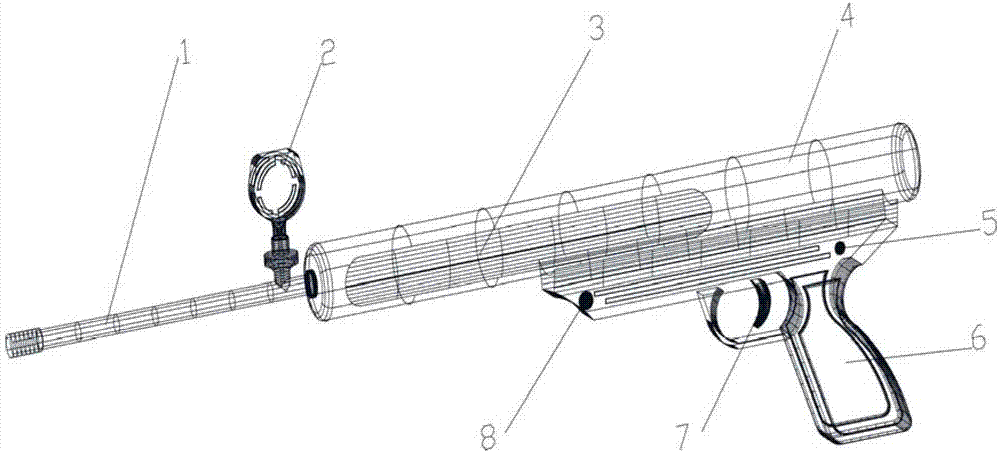

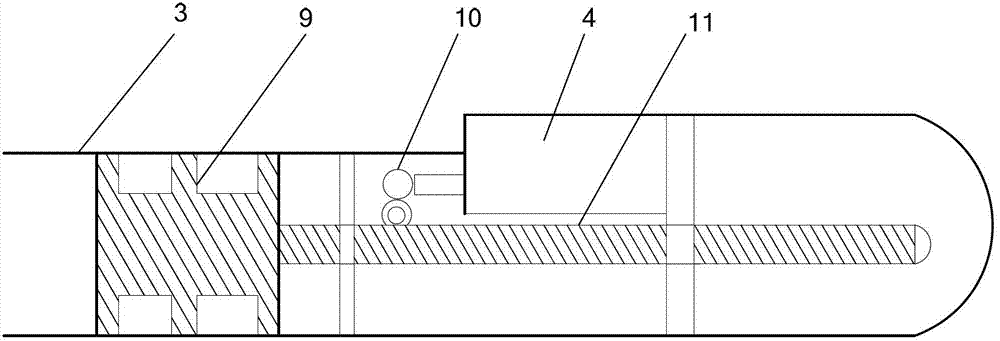

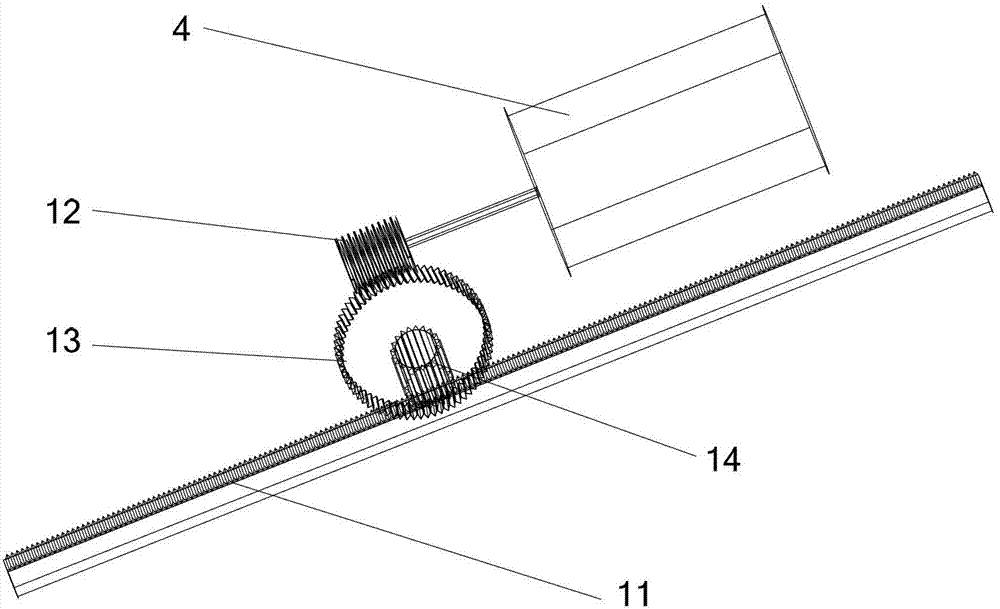

[0037] Such as figure 1 and figure 2 As shown, the present embodiment provides a pistol-shaped new quantitative type electric oil gun, which is provided with a metal oil gun chamber 3, an electric motor 4, an oil filling piston 9, and an electric motor 4 are arranged in the oil gun chamber. The gear transmission mechanism 10 is meshed with the oil injection piston to convert the torque output by the electric motor into thrust, and push the oil injection piston to move linearly towards the oil injection port 1 of the oil gun, thereby pushing the oil in the oil gun cavity to the oil injection port of the oil gun , to complete the operation of oiling the equipment. In this embodiment, the oil injection piston can adopt a three-ring two-layer piston, which has good air tightness and low resistance, thereby reducing energy consumpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com