Bellows mechanical sealing device with self-circulation function

A mechanical seal device, bellows technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the difficulty of reasonable design and selection of mechanical seals, the short axial space of the pump body seal cavity, and the large heat load of seal flushing. and other problems, to achieve the effect of good followability, compact structure and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

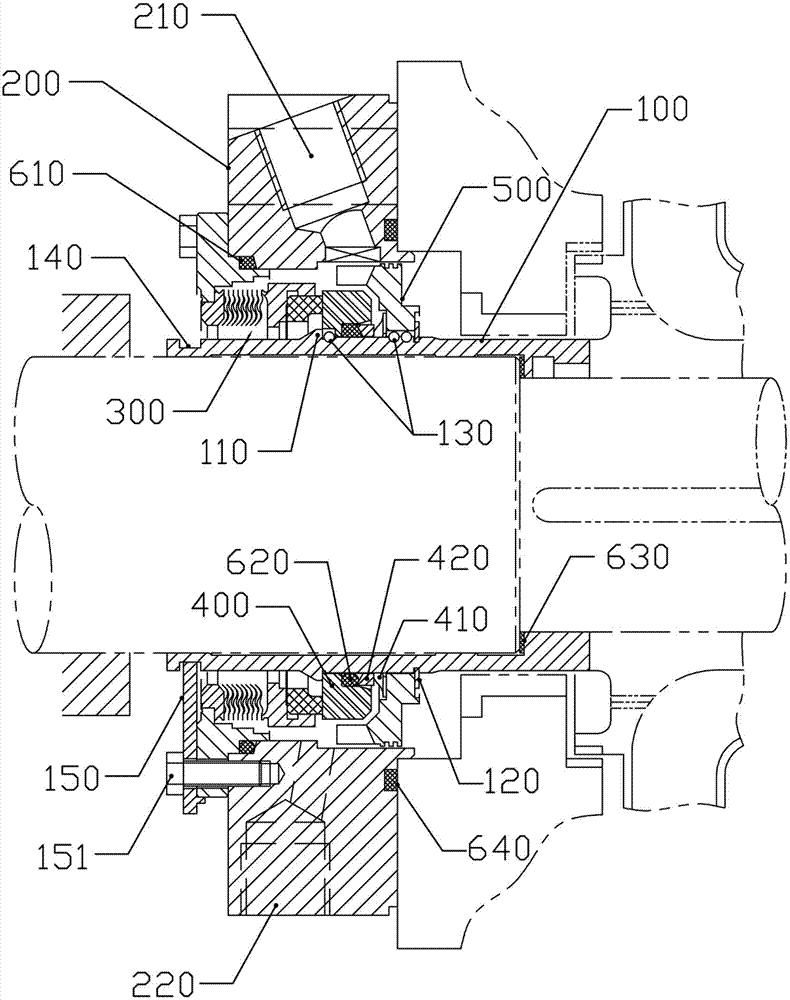

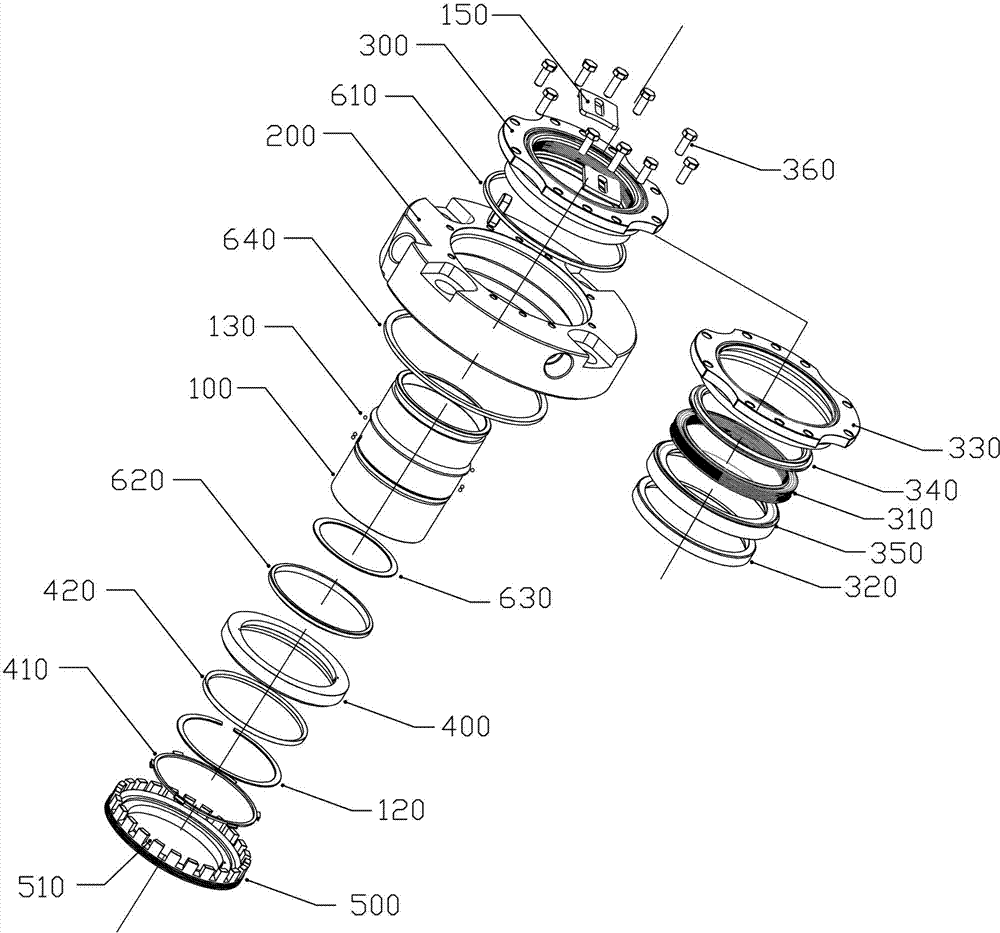

[0020] refer to figure 1 and figure 2 , a bellows mechanical seal device with self-circulation, including a shaft sleeve 100, a sealing gland 200, an elastic compensation assembly 300, a moving ring 400, an auxiliary seal and a pump effect ring 500, and the sealing gland 200 is provided with a flushing outlet 210 The location of the flush inlet 220 and the flush outlet 210 corresponds to the outer wall of the pump effect ring 500 .

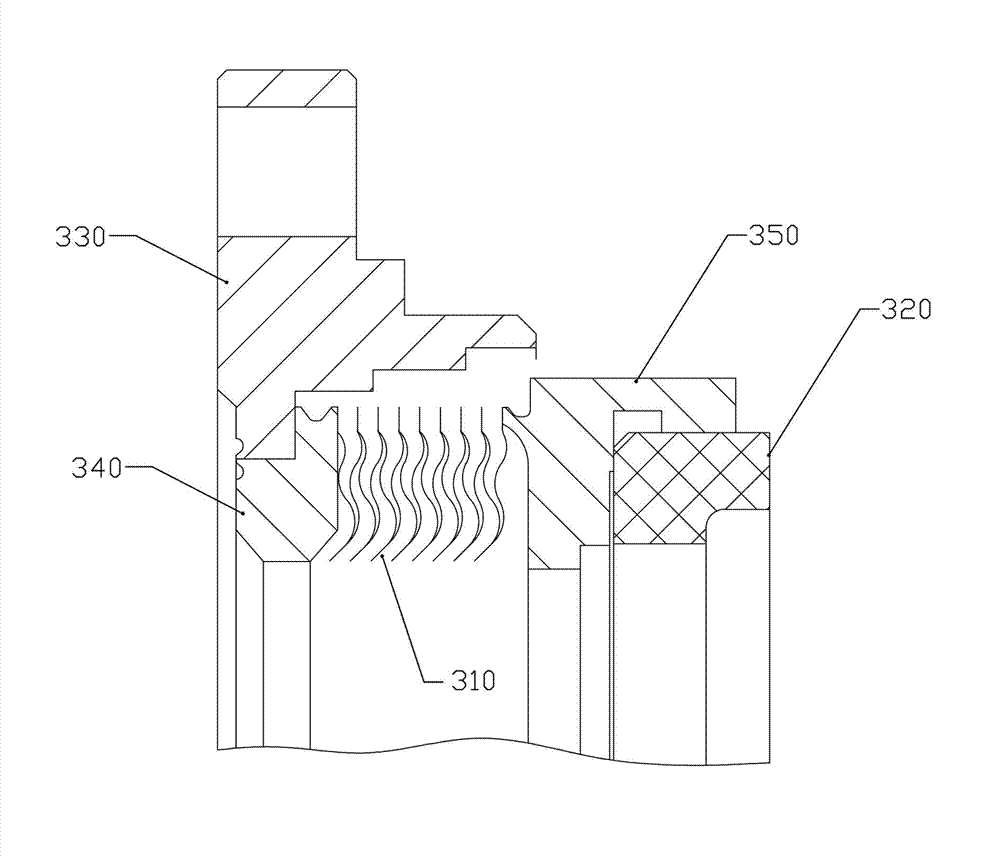

[0021] refer to image 3 The elastic compensation assembly 300 includes a bellows 310, a static ring 320, an annular end cover 330, a transition ring 340 and a static ring seat 350, the bellows 310 is a welded metal bellows, and the transition ring 340 and the static ring seat 350 are respectively sealed and welded to At both ends of the bellows 310, the static ring 320 is inlaid on the static ring seat 350, and the transition ring 340 is welded on the end cover 330, and the end cover 330 is fixed on the sealing gland 200 by eight uniformly dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com