An explosion-proof engine and an explosion-proof fire truck using the explosion-proof engine

An engine and cylinder block technology, applied in the direction of engine cooling, engine sealing device, engine components, etc., can solve the problems of igniting and detonating dangerous gases, and achieve the effect of huge commercial value and good explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

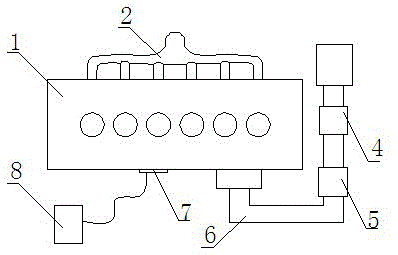

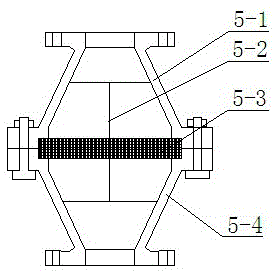

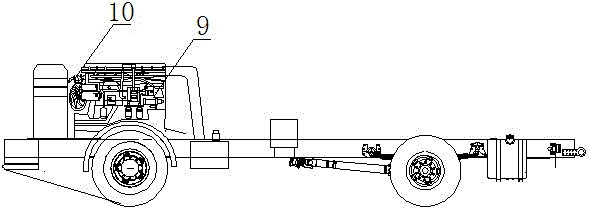

[0018] Such as figure 1 , figure 2 Shown: the explosion-proof engine of the present invention includes a cylinder block, a cylinder head 1, an air intake system and an exhaust system, and the junction between the cylinder block and the cylinder head 1 adopts a flameproof joint surface, and the cylinder body and the cylinder head 1 The width of the peripheral joint surface is not less than 20 mm, and the joint gap between the cylinder body and the cylinder head 1 is not greater than 0.15 mm. This reliably prevents the leakage of high-temperature gas inside the engine cylinder, and avoids secondary disasters such as combustion and explosion of external flammable and explosive gases. Described air intake system adopts anti-explosion air intake system, and this explosion-proof air intake system comprises air intake pipe 6, and booster pump 4 and flame arrester 5 are arranged on air intake pipe 6, and described flame arrester 5 can avoid external combustion to engine internal ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com