Novel electro-hydraulic integral bridge plug release tool

A bridge plug and tool technology, applied in the field of new electro-hydraulic integrated bridge plug delivery tools, can solve the problems of low efficiency and long working time, and achieve good bidirectional pressure bearing capacity, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

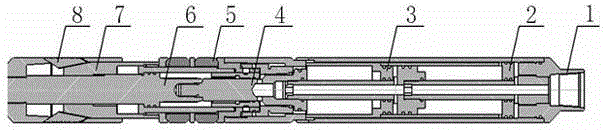

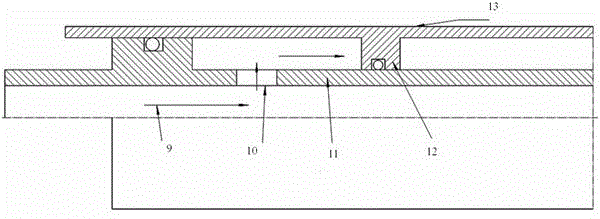

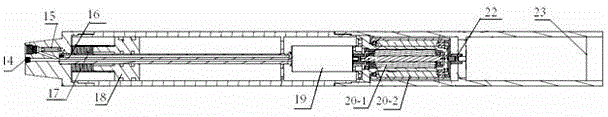

[0022] A novel electro-hydraulic integrated bridge plug delivery tool is characterized in that it includes a removable bridge plug, a hydraulic joint and a piston cylinder 13, and the removable bridge plug is composed of an upper piston 2, a lower piston 3, a tension rod 4. The mandrels 6 are connected in series in sequence, the rear end of the upper piston 2 is connected to the hydraulic electric pump interface 1, the tension rod 4 is covered with a rubber tube 5, and the mandrel 6 is covered with a slip cone 7, a slip 8 and a slip cone 7 At the rear end of the slips 8; the hydraulic nipple is composed of a check valve 14, a relief valve 15, a high and low pressure oil pipe 16, a pressure balance piston 18, a hydraulic electric pump 19, a magnetic coupling 20, a shaft coupling 21, The motor 22 and the fuel tank 25 are composed of one end of the high and low pressure oil pipe 16 covered with a pressure balance piston 18 respectively connected with the one-way valve 14 and the o...

Embodiment 2

[0024] Such as figure 1 with image 3 As shown, a new electro-hydraulic integrated bridge plug delivery tool includes a removable bridge plug, a hydraulic nipple and a piston cylinder 13. The removable bridge plug is composed of an upper piston 2, a lower piston 3, a tension rod 4, a core Axis 6 is connected in series in sequence, the rear end of upper piston 2 is connected to hydraulic electric pump interface 1, tension rod 4 is covered with rubber tube 5, mandrel 6 is covered with slip cone 7, slip 8 and slip cone 7 is in the slip 8 rear end; the hydraulic joint is composed of check valve 14, overflow valve 15, high and low pressure oil pipe 16, pressure balance piston 18, hydraulic electric pump 19, magnetic coupling 20, shaft coupling 21, motor 22 and The oil tank 25 is composed of one end of the high and low pressure oil pipe 16 jacketed with a pressure balance piston 18 respectively connected with the one-way valve 14 and the overflow valve 15, and the other end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com