Preparation method of super-hydrophobic polyester textile

A textile and superhydrophobic technology, applied in textiles and papermaking, fiber treatment, fiber types, etc., can solve problems such as poor fiber affinity, poor durability of superhydrophobic fabrics, and solvent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

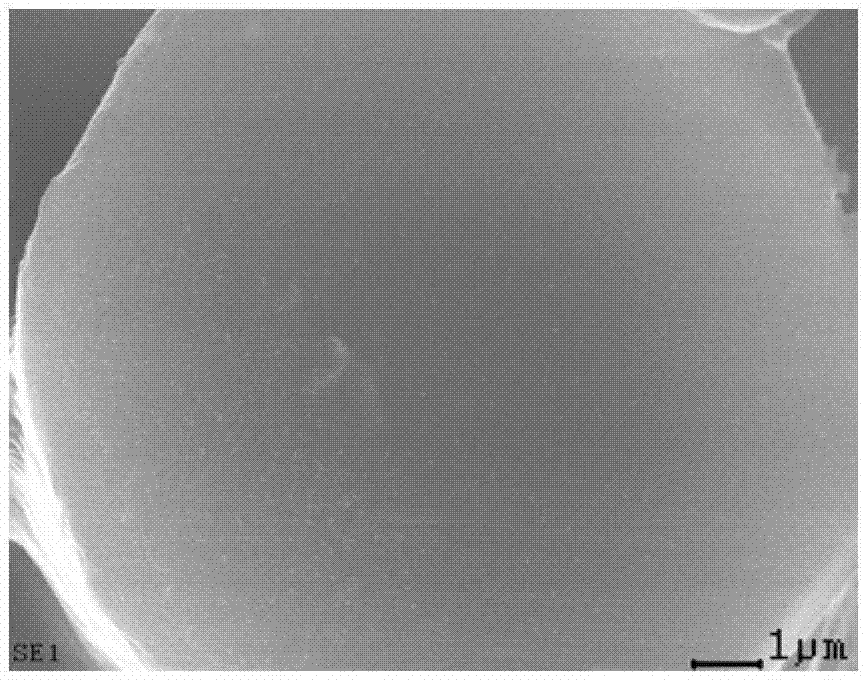

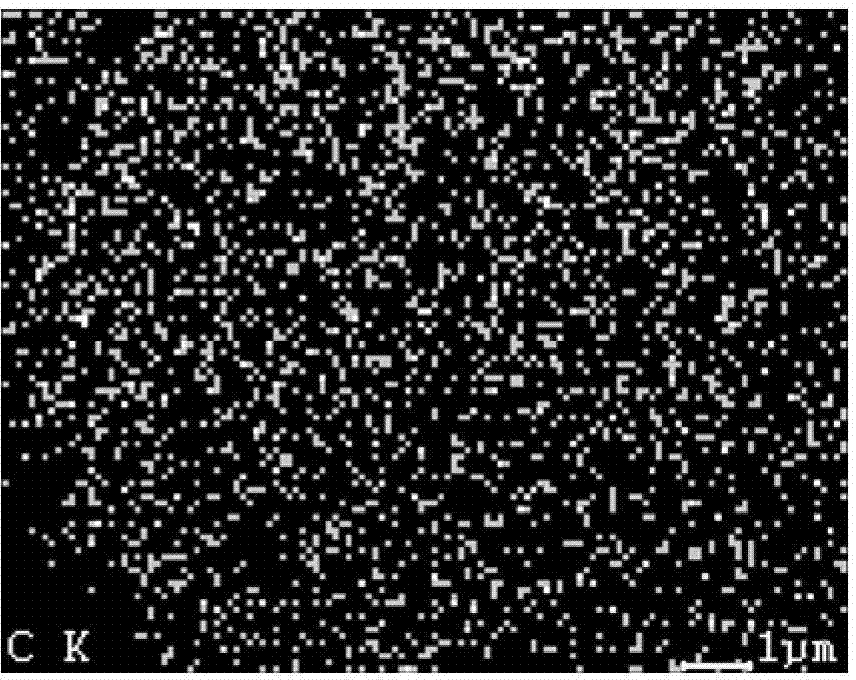

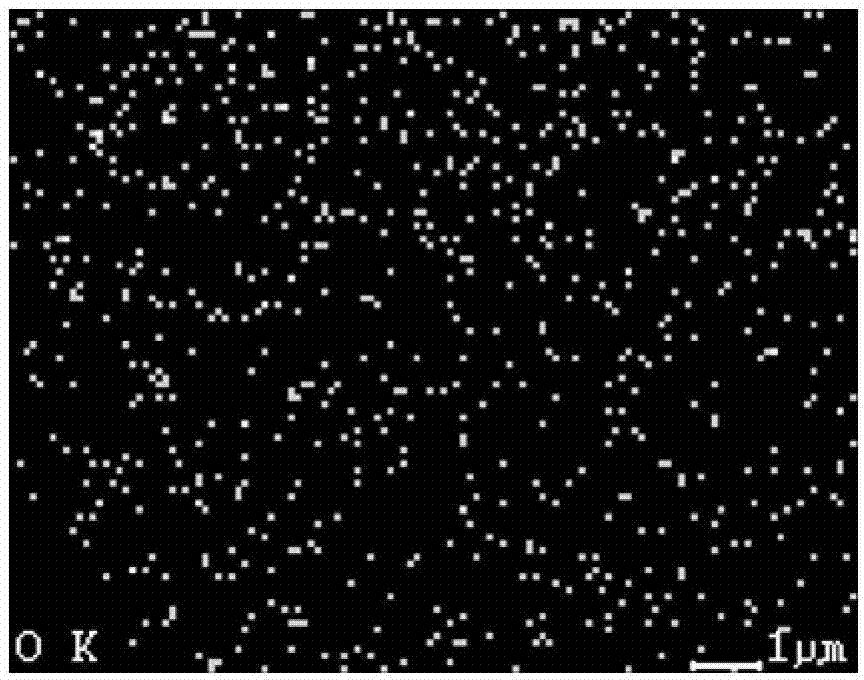

Image

Examples

Embodiment 1

[0030] Step 1: Treat polyester fabric with alkali: first soak the polyester fabric in warm water at a temperature of 40°C, then immerse the fabric in a bath ratio of 40:1, a concentration of sodium hydroxide of 5g / L, and a concentration of accelerator 1227 of 2g / L of finishing solution, heated at 90°C for 50min, and finally took out the fabric, fully washed it with deionized water, and dried it at 80°C to obtain an alkali-treated polyester fabric.

[0031] Step 2: In the absence of solvent, place the alkali-treated polyester fabric in a dyeing vat, add 30% heptadecafluorodecyltrimethoxysilane to the fabric weight, seal it, treat it at 130°C for 1 hour, and take out the fabric Bake at 70°C for 90min. The surface contact angle of the obtained fabric is 159.6 °, and after the obtained fabric is worn 2000 times on the AATCC color fastness tester against rubbing, its contact angle with water droplets is 155.5 °, and the soap powder boiling water with a solubility of 5g / L After me...

Embodiment 2

[0033] Step 1: Treat polyester fabric with alkali: first soak the polyester fabric in warm water, then immerse the fabric in a finishing solution with a bath ratio of 40:1, a sodium hydroxide concentration of 5g / L, and an accelerator 1227 concentration of 2g / L , heated at 90°C for 50min, and finally the fabric was taken out, fully washed with deionized water, and dried at 80°C to obtain an alkali-treated polyester fabric.

[0034] Step 2: In the absence of solvent, place the alkali-treated polyester fabric in a dye vat, add 30% hexadecyltrimethoxysilane to the weight of the fabric, seal it, treat it at 150°C for 0.5h, and take out the fabric Bake at 100°C for 60 minutes. The surface contact angle of the obtained fabric is 161.2 °, and after the obtained fabric is worn 2000 times on the AATCC color fastness tester against rubbing, its contact angle with water droplets is 153.2 °, and the soap powder boiling water with a solubility of 5g / L After medium cooking for 180min, the c...

Embodiment 3

[0036] Step 1: Treatment of polyester fabric with alkali: first soak the polyester fabric in warm water, then immerse the fabric in a finishing process with a bath ratio of 40:1, a sodium hydroxide concentration of 18g / L, and an accelerator 1227 concentration of 1.5g / L solution, heated at 90°C for 50min, and finally the fabric was taken out, fully washed with deionized water, and dried at 80°C to obtain an alkali-treated polyester fabric.

[0037] Step 2: In the absence of solvent, place the alkali-treated polyester fabric in a dyeing vat, add 10% heptadecafluorodecyltrimethoxysilane to the weight of the fabric, seal it, treat it at 100°C for 1.5h, and take out the fabric Bake at 150°C for 30min. The surface contact angle of the obtained fabric is 163.8 °, and after the obtained fabric is worn 2000 times on the AATCC color fastness tester against rubbing, its contact angle with water droplets is 156.9 °, and the soap powder boiling water with a solubility of 5g / L After medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com