Diesel anti-wear agent

An anti-wear agent and diesel technology, applied in the field of fuel additives, can solve problems such as wear and damage of fuel pumps, and achieve the effects of reducing emissions, protecting the environment, and improving the lubricating performance of diesel fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

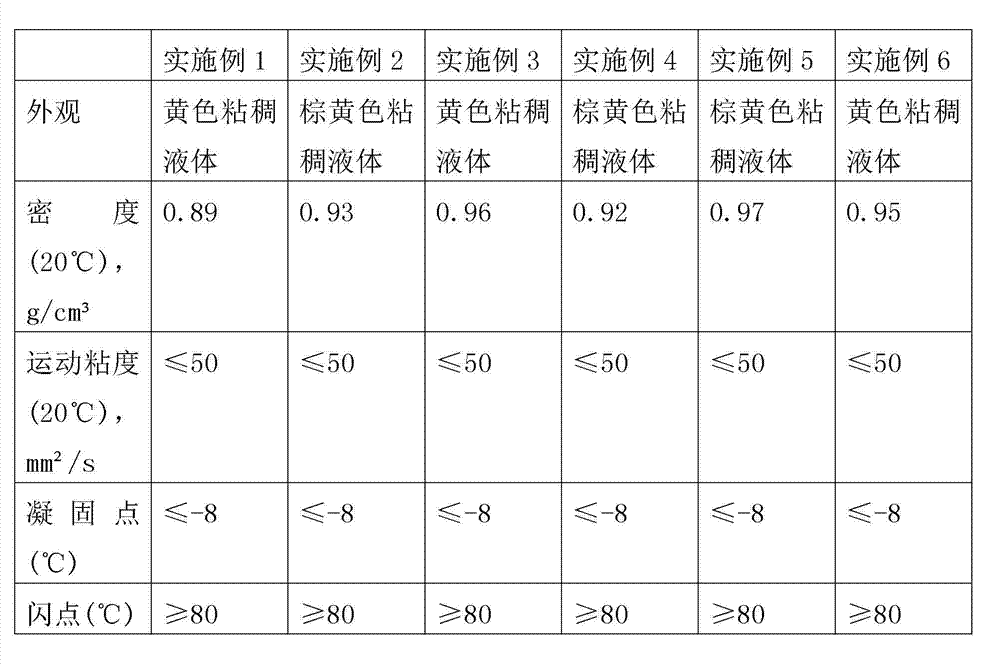

Examples

Embodiment 1

[0017] 1. Preparation of ricinoleic acid monoglyceride: add 50kg ricinoleic acid and 10kg glycerol to the reaction kettle, then add 3kg solvent oil, and add 1kg of concentrated sulfuric acid with a mass concentration of 98% as a catalyst, and remove water under reflux After 5-6 hours, after the esterification reaction, the resulting material is washed with water to remove the acidic catalyst, and finally the material is dehydrated by vacuum distillation to obtain ricinoleic acid monoglyceride.

[0018] 2. Compounding: first add 30kg ricinoleic acid into the reaction kettle, heat up to 100-110°C, keep for 1 hour to remove the water, then cool down to below 50°C, add 70kg ricinoleic acid monoglyceride, stir well and serve as diesel anti-wear agent.

Embodiment 2

[0020] 1. Preparation of ricinoleic acid monoglyceride: 50kg ricinoleic acid and 11kg glycerol are added to the reaction kettle, then 3.3kg solvent oil is added, and 0.9kg mass concentration of 98% concentrated sulfuric acid is added as a catalyst. Remove water for 5-6 hours, after the esterification reaction, wash the resulting material with water to remove the acidic catalyst, and finally distill under reduced pressure to dehydrate the material to obtain ricinoleic acid monoglyceride.

[0021] 2. Compounding: firstly add 30kg ricinoleic acid into the reaction kettle, raise the temperature to 100-110°C, keep for 1 hour to remove the water, then cool down to below 50°C, add 68kg ricinoleic acid monoglyceride, stir well and serve as diesel anti-wear agent.

Embodiment 3

[0023] 1. Preparation of ricinoleic acid monoglyceride: 52kg ricinoleic acid and 9.5kg glycerol are added to the reaction kettle, then 2.8kg solvent oil is added, and 1kg mass concentration is added as 98% concentrated sulfuric acid as a catalyst, under reflux state Remove water for 5-6 hours, after the esterification reaction, wash the resulting material with water to remove the acidic catalyst, and finally distill under reduced pressure to dehydrate the material to obtain ricinoleic acid monoglyceride.

[0024] 2. Compounding: First add 31kg ricinoleic acid into the reaction kettle, heat up to 100-110°C, keep for 1 hour to remove the water, then cool to below 50°C, add 72kg ricinoleic acid monoglyceride, stir well and serve as diesel anti-wear agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com