Preparation method of ornithine aspartate

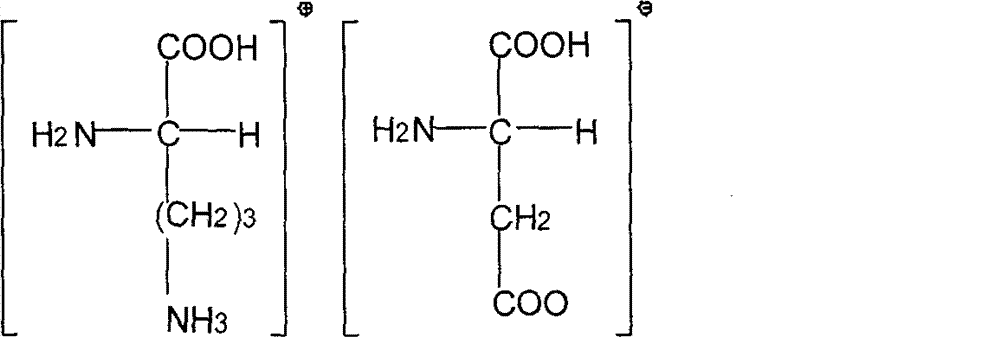

A technology of ornithine aspartate and ornithine hydrochloride, applied in the field of preparation of ornithine aspartate, can solve the problems of high cost, large pollution, and easy generation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] (1) Desalination of L-ornithine hydrochloride

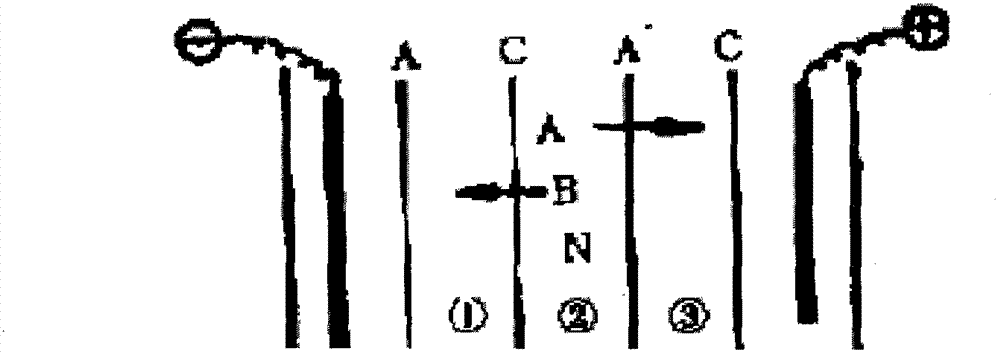

[0029] Take 168g of L-ornithine hydrochloride, add 500ml of water to dissolve, add 40% sodium hydroxide to adjust the pH value to 11.0 (L-ornithine isoelectric point); add water to make the volume to 1000ml, in the two-stage recovery chamber of the electroosmosis device Add 0.1 mol / L hydrochloric acid and sodium hydroxide solution to each, adjust the voltage to 20 volts, and then pass the above-mentioned L-ornithine solution through the electrodialyzer at a rate of 20 ml per minute. L silver nitrate solution to check whether the chloride ions have been removed cleanly, collect the chloride-free solution for the next step.

[0030] (2) Preparation of ornithine aspartate

[0031] Take the above desalted ornithine solution and add 132g of L-aspartic acid, adjust the pH to 5.0-7.0, until insoluble matter appears in the solution (excess aspartic acid), filter to remove excess aspartic acid , The solution was decolorized with 1.0% ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com