Floating drum aeration blender

A mixer and buoy technology, which is applied in the field of buoy aeration mixer, can solve the problems of bearing and bushing wear, water inlet blockage, and reduced service life, and achieve the goals of improving wear resistance and strength, convenient installation, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

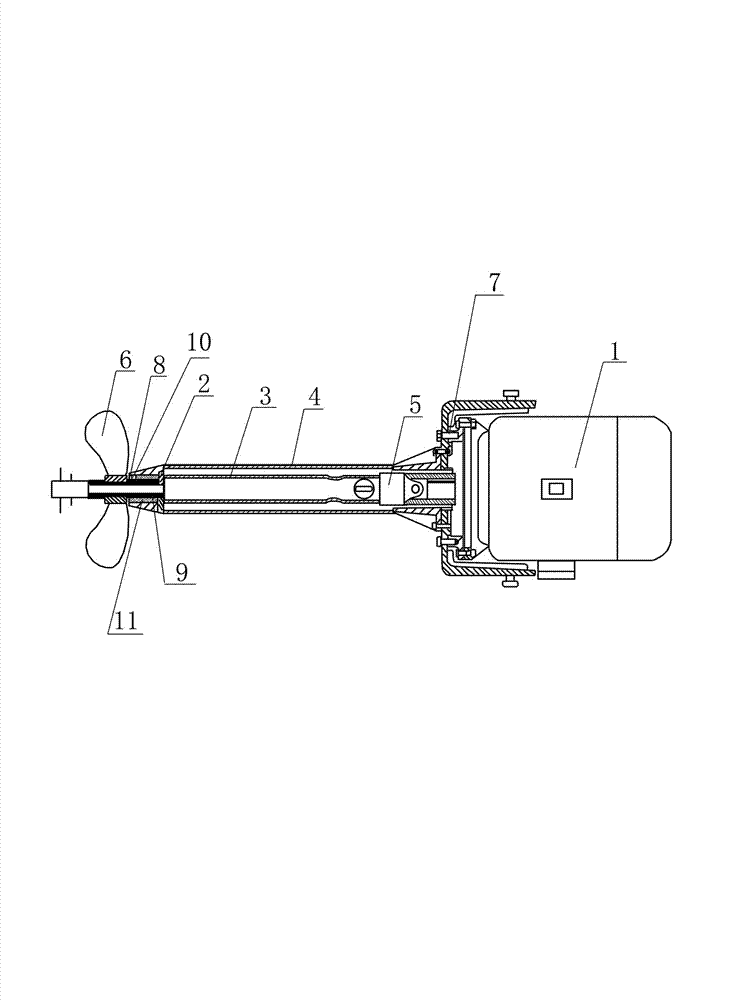

[0009] In Fig. 1 and Fig. 2, the present invention provides a buoyant aeration mixer, which includes a mixer main body and a buoy, the buoy is a stuffed buoy, the buoy is set on the mixer main body, and the mixer main body includes a motor 1, a connecting shaft 2 and The composite impeller includes the inner shaft 3 and the casing 4 from the inside to the outside of the connecting shaft 2. The output end of the motor 1 is connected to the blade 6 of the composite impeller through the coupling 5 and the inner shaft 3 in turn. The blade 6 of the composite impeller is made of glass fiber reinforced plastic Blades, the blades 6 of the compound impeller are set in a fan-shaped structure inclined forward, the front end of the casing 4 is adjacent to the compound impeller, the rear end of the casing 4 is connected to the motor 1 through the flange 7, and the inner wall of the front end of the casing 4 is connected to the A shaft sleeve 8 and a bearing 9 are sequentially arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com