Tower crane safety management system

A technology of safety management and safety management platform, applied in the field of tower crane safety management system, can solve the problems of reduced reliability, shortened service life and high cost, and achieve the effect of high reliability, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

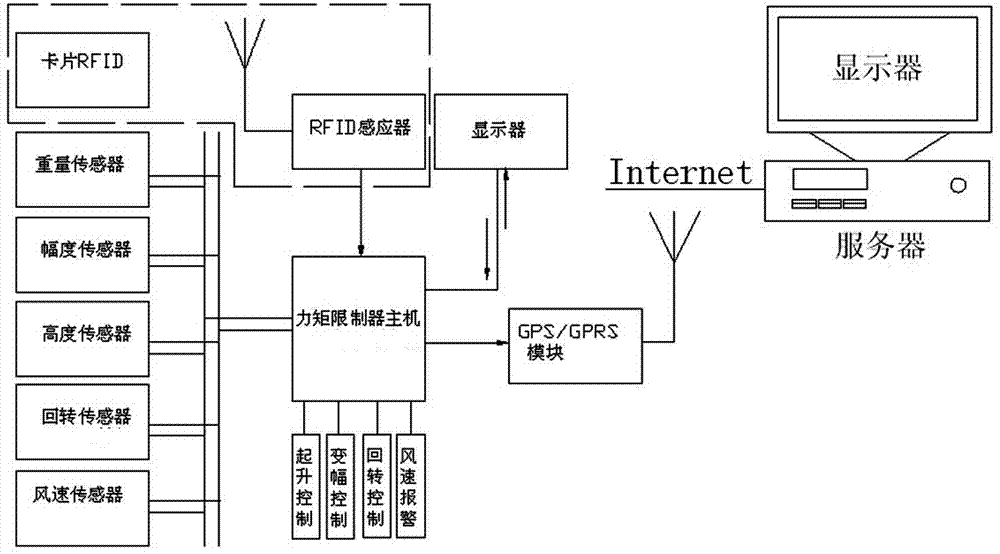

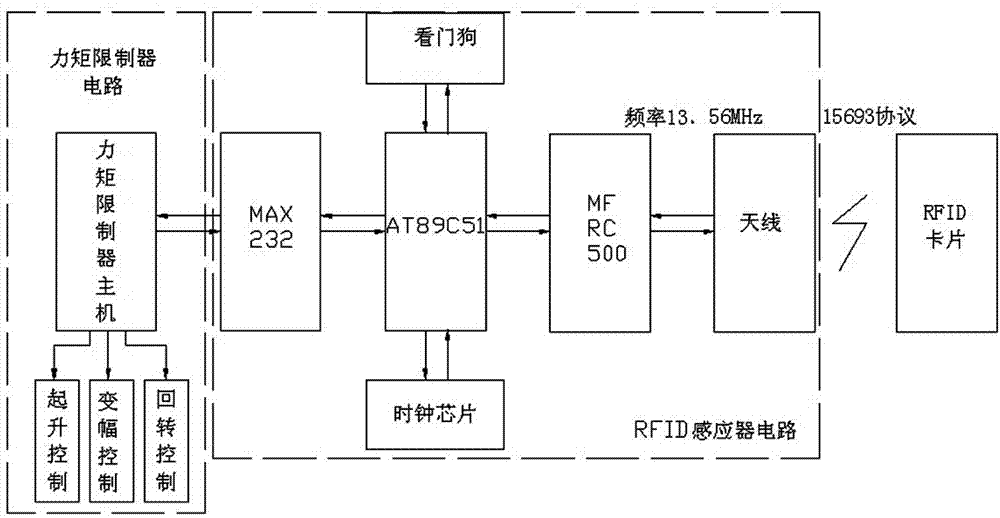

[0025] A tower crane safety management system of the present invention comprises: a server, a tower crane safety management platform, a GPS / GPRS communication module, a torque limiter host with RFID management function, and the torque limiter host is provided with an RFID sensing chip and an RFID sensor , the torque limiter host is respectively connected with: weight sensor, amplitude sensor, height sensor, rotation angle sensor, wind speed sensor through CAN bus, as figure 1 shown.

[0026] work process:

[0027] When the tower crane driver is working, he first uses the RFID card to open the torque limiter host through the RFID sensor, and the torque limiter host unlocks the tower crane to enter the working state. At this time, the tower crane driver can perform various work operations. When the tower crane driver is operating in various working conditions, each sensor is also continuously sending the detected signals to the torque limiter host, and the torque limiter host p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com