High-density finely-knitted functional fabric

A fine-needle, functional technology, applied in the field of fabric manufacturing, can solve the problems of waterproof, moisture permeability, poor air permeability, uncomfortable feeling, and the performance has not been greatly improved, and achieve the effect of comfort and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

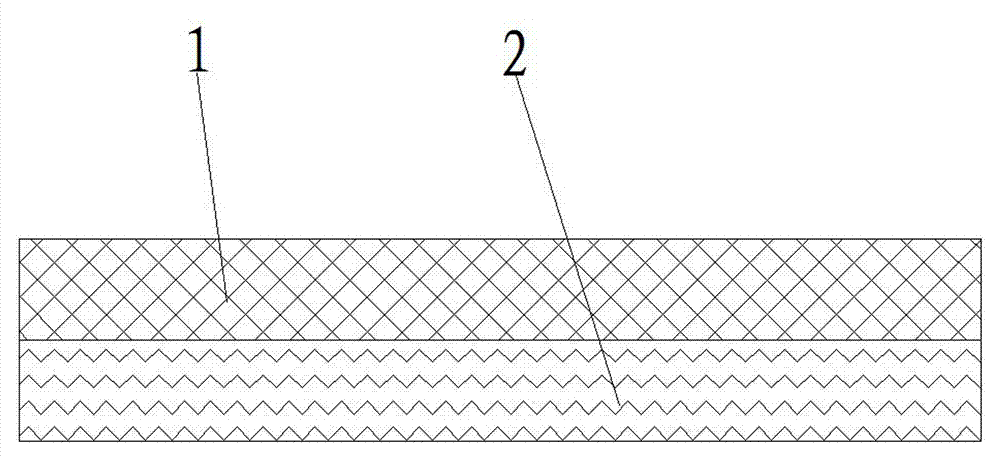

[0009] Such as figure 1 As shown, the high-density fine-needle functional cloth includes an upper mesh structure layer 1 and a lower mesh structure layer 2. The upper mesh structure layer 1 is compounded on the surface of the lower mesh structure layer 2. The upper mesh structure layer 1 and the lower mesh structure layer 2. Knitted by warp knitting respectively, using the above-mentioned technology, the present invention has the style of knitting imitation weaving, comfortable elasticity, delicate style, waterproof, windproof and breathable function, and is suitable for making down jackets, outdoor functional fabrics, and various printings , embossed and cloud styles.

[0010] Finally, it should be noted that: the above embodiments are only used to illustrate the technical solutions of the present invention without limitation, although the present invention has been described in detail with reference to the preferred embodiments, those of ordinary skill in the art should unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com