Method for winding rectangular tube by glass reinforced plastic fibers

A glass fiber reinforced plastic, rectangular tube technology, applied in the direction of tubular items, other household appliances, household appliances, etc., to achieve uniform distribution, improve winding quality, and stabilize sliding lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

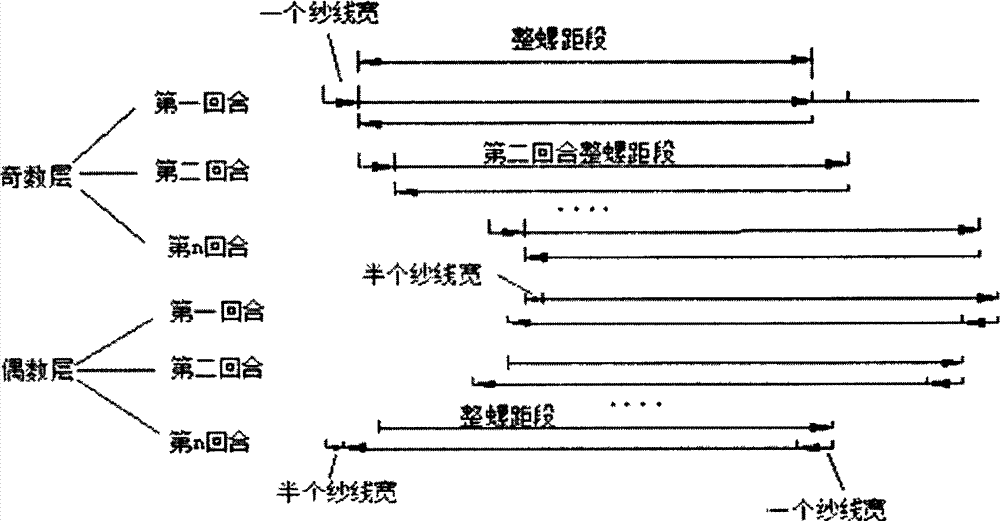

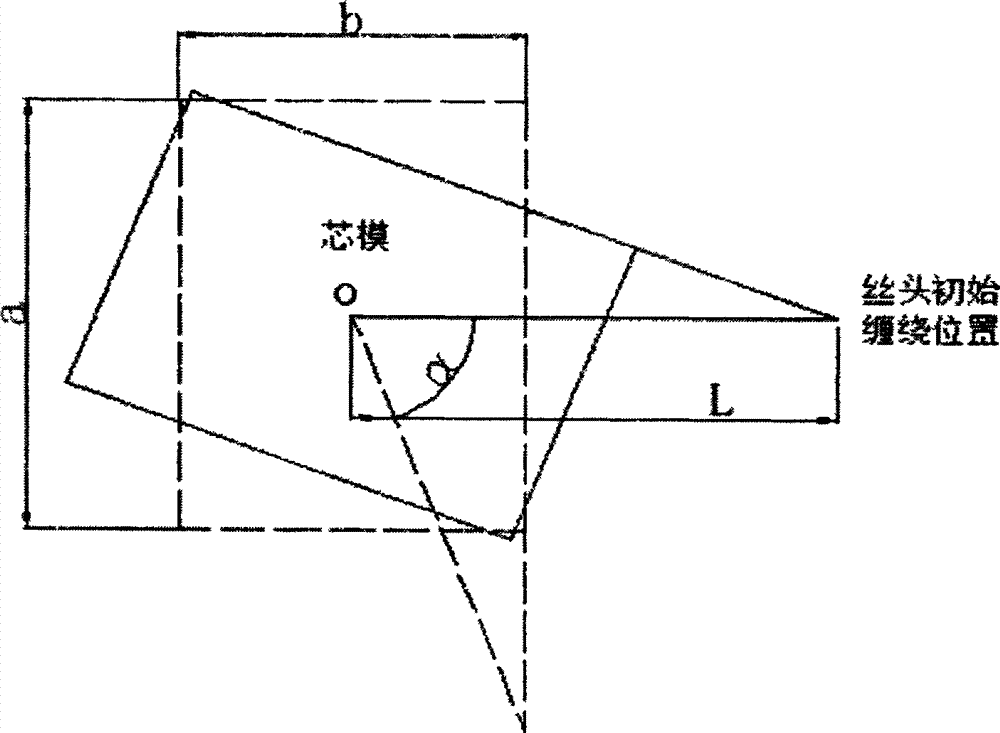

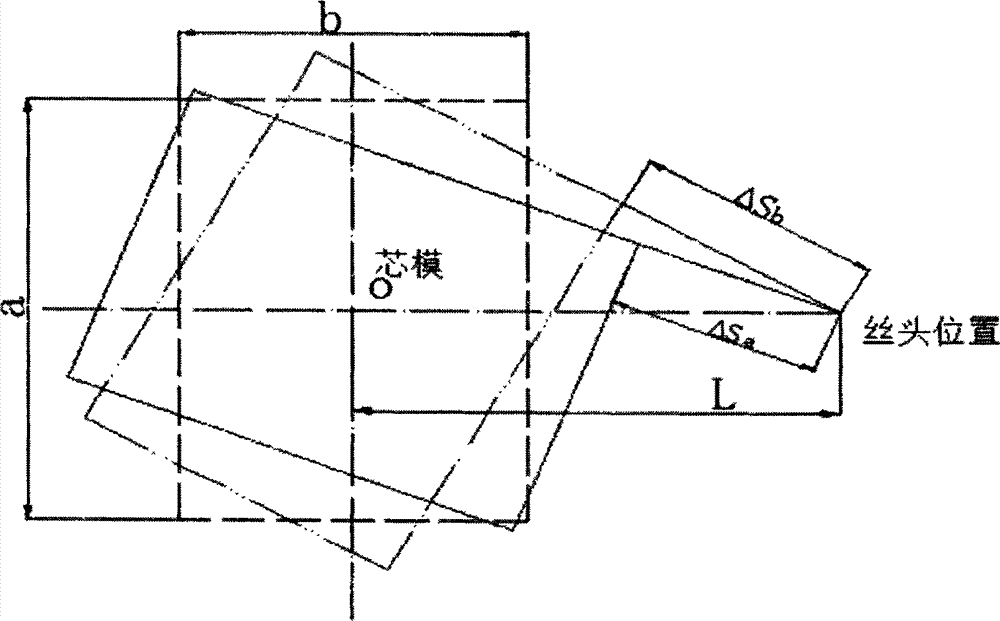

[0015] Through research and actual investigation, it is found that the current winding methods for non-revolving bodies such as rectangular pipes are mostly based on the winding principle of rotating bodies such as circular pipes. When winding a rotating body such as a circular tube, the fiber direction changes gradually with the outer surface of the circular tube, and each point on the outer wall of the circular tube can be used as a fiber doffing point; when winding a rectangular tube, the fiber direction follows the outer surface of the rectangular tube. The surface change shows a stepwise mutation, and the doffing point is only the four edges of the rectangular mandrel. It can be seen that the yarn winding track is continuous when the circular tube is wound, but the yarn winding track is discontinuous when the rectangular tube is wound. The present invention is just to solve the linear design and implementation scheme specially proposed for the shape of the rectangular tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com