Steel plate cutting bed die

A technology of steel plates and bottom molds, applied in the direction of workbenches, manufacturing tools, etc., can solve problems such as impact, increase cost, ground damage, etc., and achieve the effect of preventing damage and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

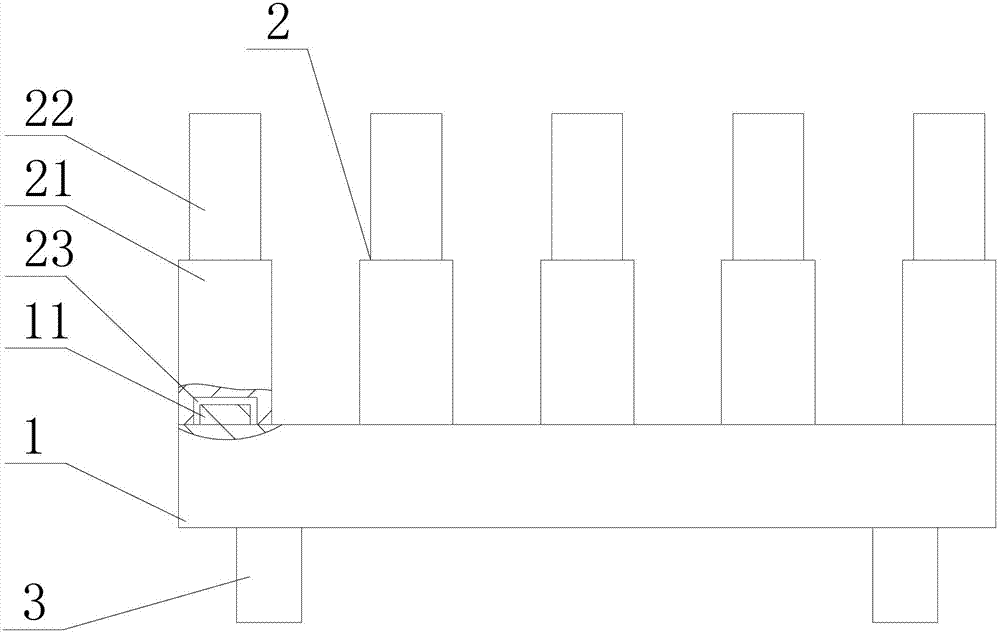

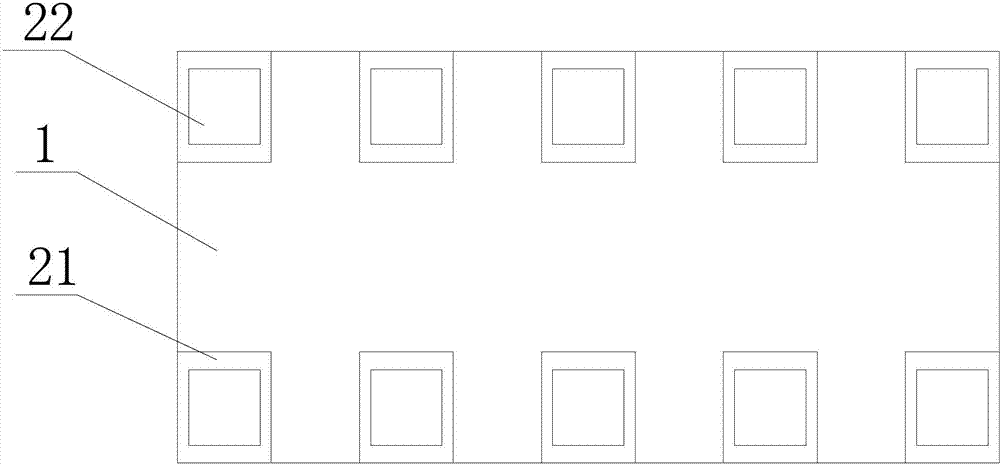

[0015] Such as figure 1 , figure 2 As shown, the steel plate cutting bottom mold includes a base plate 1, several height-adjustable support plates 2 for placing steel plates, the bottom ends of the support plates 2 are buckled on the base plate 1, and the bottom surface of the base plate 1 is provided with Mobile device 3, described support plate 2 comprises connecting rod 21, the supporting rod 22 that is movably connected on connecting rod 21, and described connecting rod 21 and supporting rod 22 are movably connected by thread, also can be other connection devices that are convenient for activities, The thread adjustment is reliable and easy to use. The bottom plate 1 is provided with a connecting rod 21 to fix the insert 11, and the bottom end of the connecting rod 21 is provided with a jack 23 that cooperates with the insert 11, which is convenient for installation. The support plate 2 can be The use effect is good. The support plate 2 is fixed on the bottom plate 1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com