Method for realizing on-line measurement of multi-purpose measuring head for vertical numerically controlled lathe

A technology of numerical control lathes and measurement methods, applied in the direction of measurement/indicating equipment, metal processing machinery parts, metal processing equipment, etc., to achieve the effect of saving purchase and installation costs

Active Publication Date: 2015-04-08

SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of this invention is to solve the problem of on-line detection of aviation casing parts in the process of turning by using general measuring tools, and especially provides a method for on-line measurement with a multi-purpose probe for vertical numerical control lathes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0034] This embodiment provides a method for realizing online measurement with a multi-purpose probe for a vertical numerical control lathe, characterized in that: the method for realizing online measurement with a multi-purpose probe for a vertical numerical control lathe:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

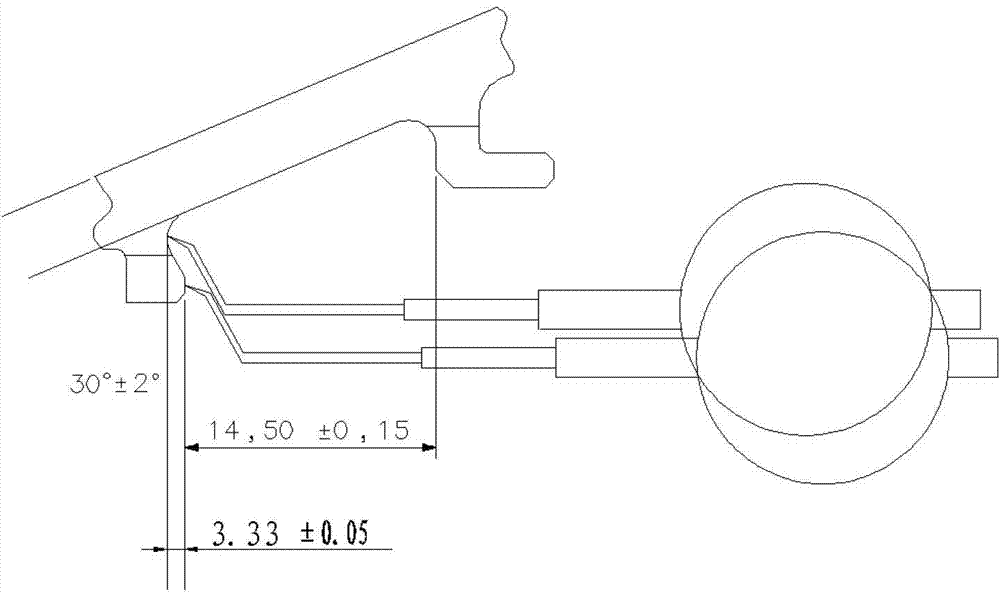

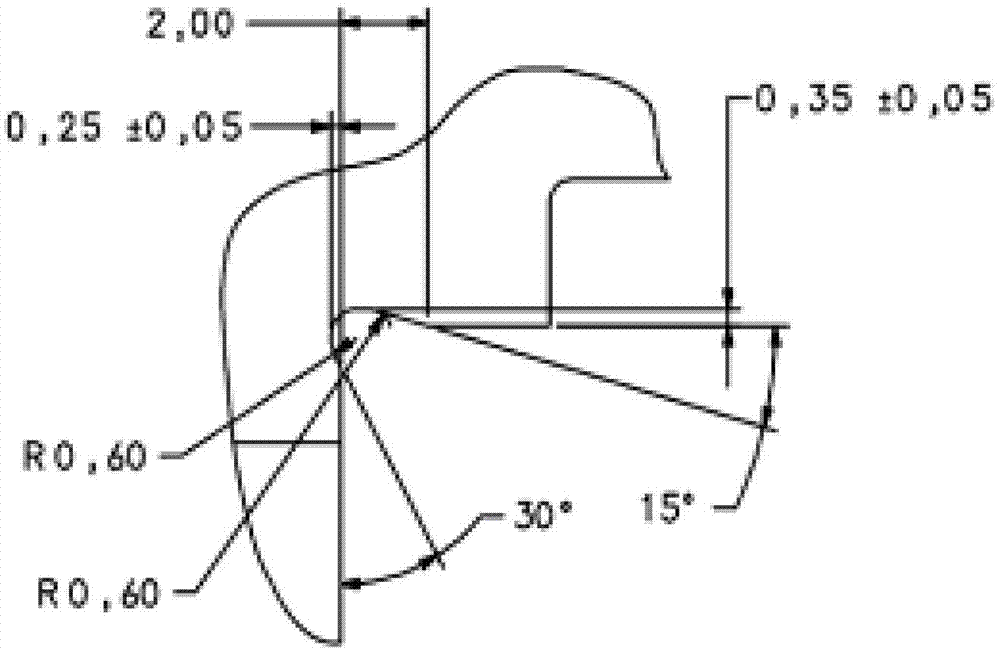

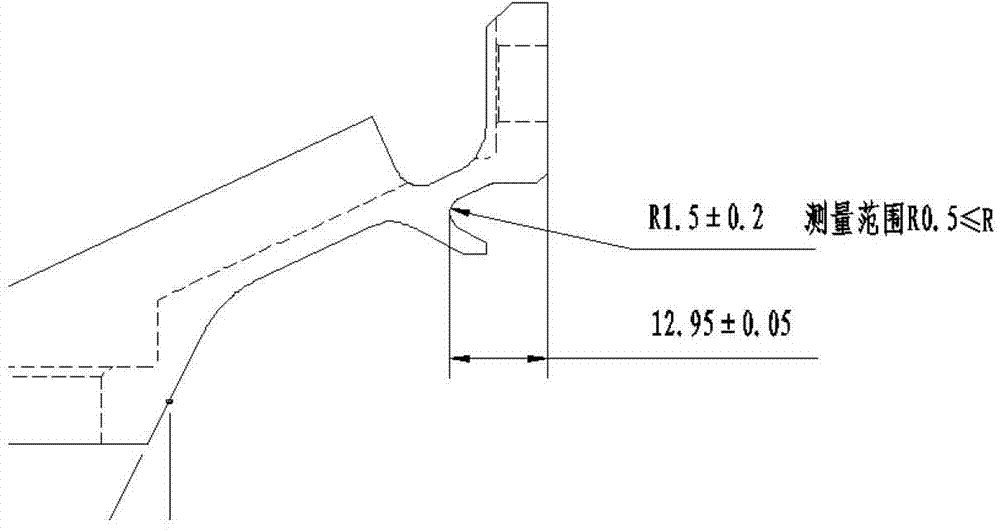

The invention discloses a method for realizing on-line measurement of a multi-purpose measuring head for a vertical numerically controlled lathe. The multi-purpose detection measuring head for the vertical numerically controlled lathe is manufactured by using a bicycle spoke; the detection measuring heads of various shapes and purposes are quickly manufactured according to part shapes and measuring requirements; the multi-purpose detection measuring head for the vertical numerically controlled lathe is connected with a universal dial indicator though thread; vertical numerically controlled lathe operation and an on-line detection technology are used cooperatively; on-line detection of size factors such as groove and arc bottom is realized by using a universal measuring tool; the dial indicator is connected with a measuring head special for on-line detection of a case adapter groove; and on-line detection of the size is performed by using a pulling mode on the machine tool. The method for realizing on-line measurement of the multi-purpose measuring head for the vertical numerically controlled lathe has the advantages of simplicity, reliability and capability of saving the purchasing and mounting cost of the on-line detection device special for modification equipment.

Description

technical field [0001] The invention relates to the field of numerical control turning, in particular to a method for realizing on-line measurement with a multipurpose measuring head for a vertical numerical control lathe. Background technique [0002] Large overall high-pressure turbine casing materials are mostly nickel-based superalloys. A large overall casing has a complex shape, high dimensional accuracy requirements, and many related dimensions. The on-line detection technology of the casing groove is even more difficult. The shape of the casing transfer groove is special, and the precision requirements are high. It cannot be detected during the turning process of the CNC lathe. Only the method of proofing paste can be used for shutdown detection or on-line detection. After processing, the parts are sent to a three-coordinate measuring machine for testing. It takes 1-2 hours to stop the test by using the proofing paste or sending the three-coordinate measuring machin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23Q17/20

Inventor 杨海涛叶红雨孙长友曹冬梅常久青

Owner SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com