Shaped deburring cutter

A technology of burr cutter and cutter body, which is applied in the attachments of tool holders, tools for lathes, turning equipment, etc., can solve the problems of narrow application range and single function, and achieve the effect of simple and applicable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate by the following examples.

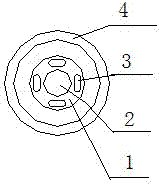

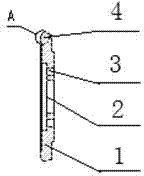

[0016] There is a shaft hole 2 in the middle of the cutter body 1, and a knife edge 4 is formed on one side of the disc-shaped cutter body 1, and arc teeth 5 are evenly distributed on the knife edge 4.

[0017] Slotted holes 3 are evenly distributed around the shaft hole 2 in the middle of the cutter body 1 .

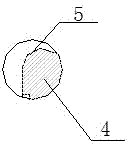

[0018] The arc teeth 5 are evenly distributed on the blade edge 4, wherein the radial ridges of the arc teeth 5 on the surface edge of the cutter body 1 are arc-shaped, and the arc teeth 5 are concave between adjacent ridges and are inclined to one side of the ridge.

[0019] In the foregoing, the upper arc teeth 5 of the knife edge 4 are composed of two opposite half circles, and their concave inclination directions are opposite. In the latter, two kinds of arc teeth 5 with opposite concave inclination directions are distributed at intervals.

[0020] When the present invention is working, it is fixed on the equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com