Special filter cylinder revolution blowing regeneration purification system for dedusting equipment and regeneration method

A technology of rotary blowing and dedusting equipment, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle filtration, etc., which can solve the problems of increased energy consumption, short service life, and poor regeneration effect of dust removal and purification equipment, and achieve dust removal and purification. Equipment energy consumption, good regeneration effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

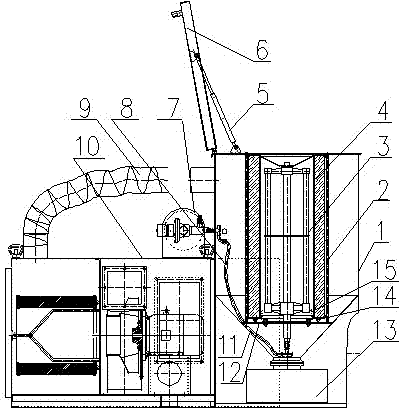

[0011] Embodiment 1: with reference to attached figure 1 . A filter cartridge rotary injection regeneration purification system for dust removal equipment is composed of a filter cartridge rotary injection regeneration equipment 1 and a gas purification equipment 10. The gas purification equipment 10 is a horizontal structure, and its manufacturing process is an existing technology, which will not be described here. ; The casing in the filter cartridge rotary injection regeneration equipment is provided with a case cover 6 and the two sides of the case cover 6 are connected with the case body through an air rod 5 , that is, a pneumatic air rod 5 . The bottom of the cabinet is provided with a material storage box 13 for storing dust. A V-shaped funnel 11 is placed on the material storage box 13 and a filter cartridge rotating blowing pipe frame 2 is placed in the V-shaped funnel 11. The structure of the filter cartridge rotating spraying pipe frame 2 is as follows: figure 1 A...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the regeneration method of the special filter cartridge rotary injection regeneration purification system for dust removal equipment, put the saturated filter cartridge 4 into the chassis and put it on the filter cartridge rotary injection pipe frame 2, pass The air rod 5 pneumatically closes the box cover 6; after the gas purification equipment 10 is started, the pure gas discharged from the purified air outlet of the gas purification equipment 10 is supplied to the booster pump 7 through the gas delivery pipe, and the pressurized air flows through the trachea 8, and the gas transmission rotates After the joint assembly distributes the high-pressure airflow, the filter cartridge is rotated and sprayed into each air-jet pipe in the pipe frame 2, and the high-pressure airflow is pressed at a certain angle through the nozzle on the air-jet pipe (it can drive the filter cartridge to rotate at an oblique angle, and the design of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com