Protective energy-saving pressure cooker

A technology of pressure cooker and pot cover, which is applied in the direction of pressure cooker, etc. It can solve the problems of large exposed area of metal surface, easy to be scalded or scalded, and unfavorable heat preservation of pressure cooker, so as to speed up the cooking process, shorten the cooking heating time, and save energy effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

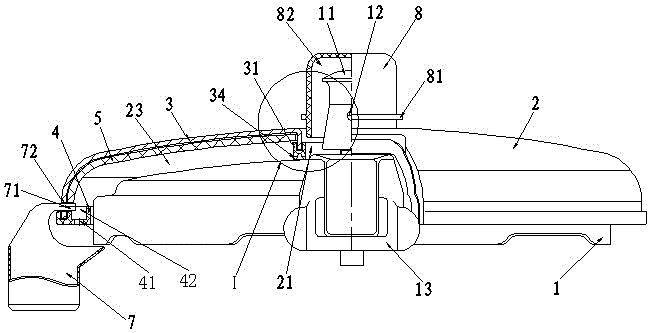

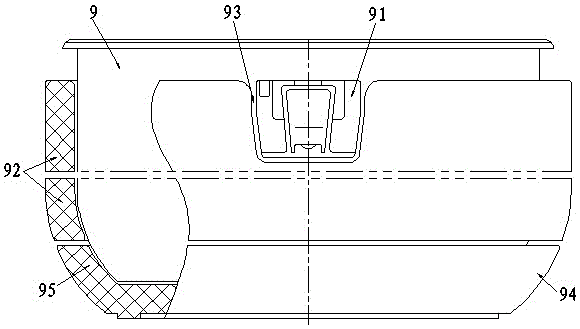

[0029] The protective energy-saving pressure cooker of the first embodiment of the present invention (for the structure see Figure 1-Figure 9 ), including a pot body 9 and a matching pot cover 1, its structural features are: the pot cover 1 is also provided with a shell cover 2 covering its surface; the shell cover 2 is composed of a metal shell 3 and a side cover 4 Combination; the metal shell 3 is made of metal sheet material, and the side cover 4 is made of plastic material;

[0030] The above-mentioned side cover 4 is in the shape of a ring, and its outer peripheral side is closely matched with the inner peripheral side of the lower end of the metal shell 3, so that the two are tightly fitted and connected to each other; the side cover 4 has an appropriate width, so that the metal shell 3 There is an appropriate distance between the inner peripheral side and the outer peripheral side of the pot cover 1; the inner peripheral side of the side cover 4 is closely attached to ...

Embodiment 2

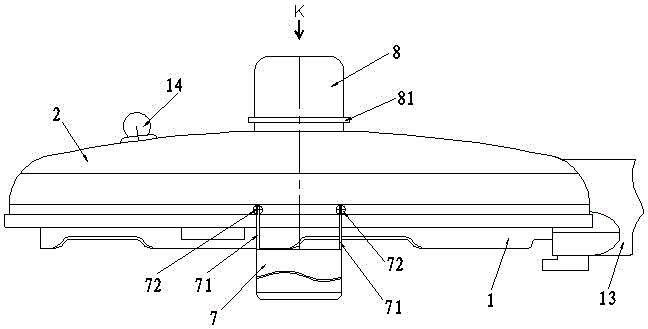

[0060] The protection and energy-saving pressure cooker of the second embodiment of the present invention (for the structure see Figure 10 to Figure 13 ), in order to make the function of the pressure cooker of the present invention more perfect, so as to make it easier to implement and apply, on the basis of the first embodiment of the present invention, the second embodiment of the present invention further configures the following structure, and its benefits are also described later.

[0061] Further structure 1: There is a suitable distance between the lower end surface of the above-mentioned hole sleeve 31 and the outer surface of the pot cover 1; the lower end of the hole sleeve 31 is provided with a ring groove 35 surrounding the pressure limiting valve; 35 sets of ring grooves A rubber ring 36 with suitable elasticity is provided, and the cross section of the rubber ring 36 is in an inverted "Y" shape, and has a preset contact deformation margin with the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com