Vermicelli cooking device

A technology of cooking powder and equipment, which is applied in food preparation, application, food science, etc., can solve the problems of incapable of large-scale production, high labor intensity of workers, and influence on product quality, and achieve easy control of water temperature, low labor intensity of workers, and fast The effect of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

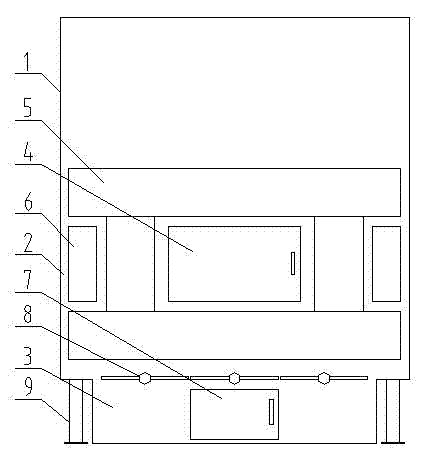

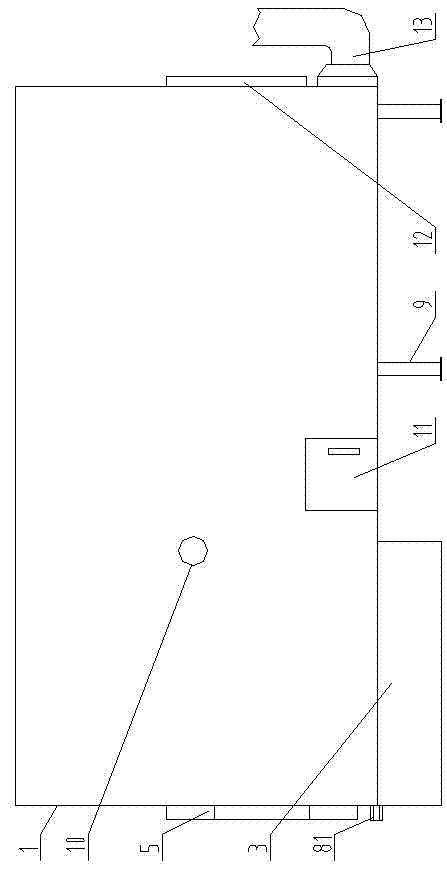

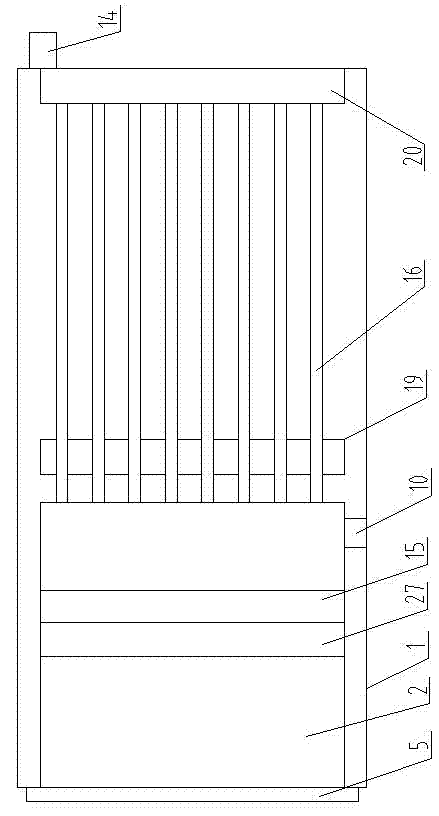

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The shown powder cooking equipment includes a powder cooking tank 1 and a furnace 2 arranged at the front end of the powder cooking tank 1, a charging door 4 is provided on the front wall of the furnace 2, a groove 15 is provided on the upper part of the furnace 2, and a furnace 2 is provided inside the furnace 2. There is a front burner 22 connected to the inner side of the groove 15, and an air distribution hole 25 is arranged on the inner side of the front burner 22. A rear burner 23 is provided between the front burner 22 and the rear wall of the furnace 2, and the rear burner 23 is as high as the front burner 22. Air distribution holes 25 are all provided on the front and rear sides of the rear burner 23. The gasification chamber 26 is formed above the front burner 22 and the rear burner 23, and air ducts 6 are arranged on both sides of the furnace 2, and the two ends of the front burner 22 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com