Driving method and driving circuit of liquid crystal panel and liquid crystal display device

A technology of a liquid crystal panel and a driving method, applied in static indicators, instruments, etc., can solve the problems of increasing cost and occupying space on the edge of the glass, and achieve the effect of ensuring the duration and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

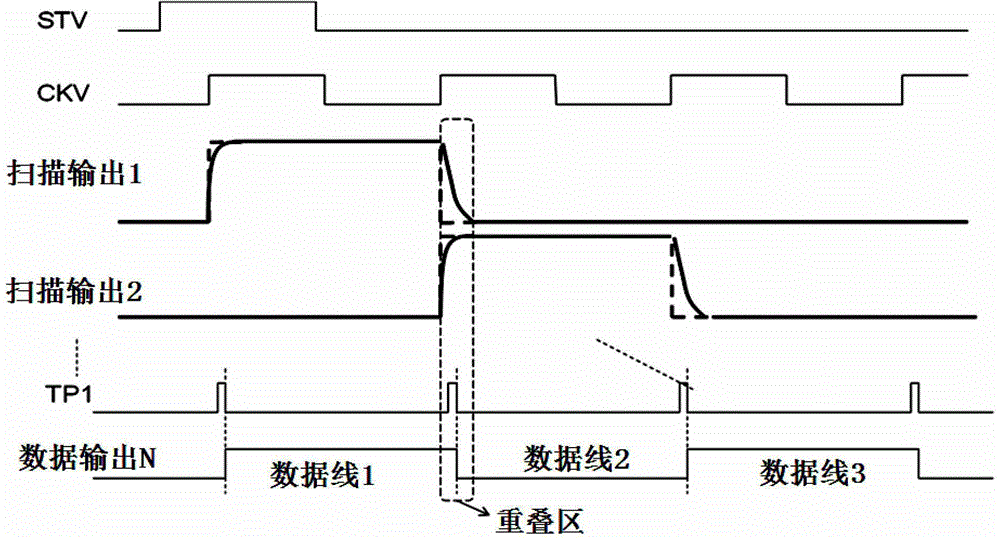

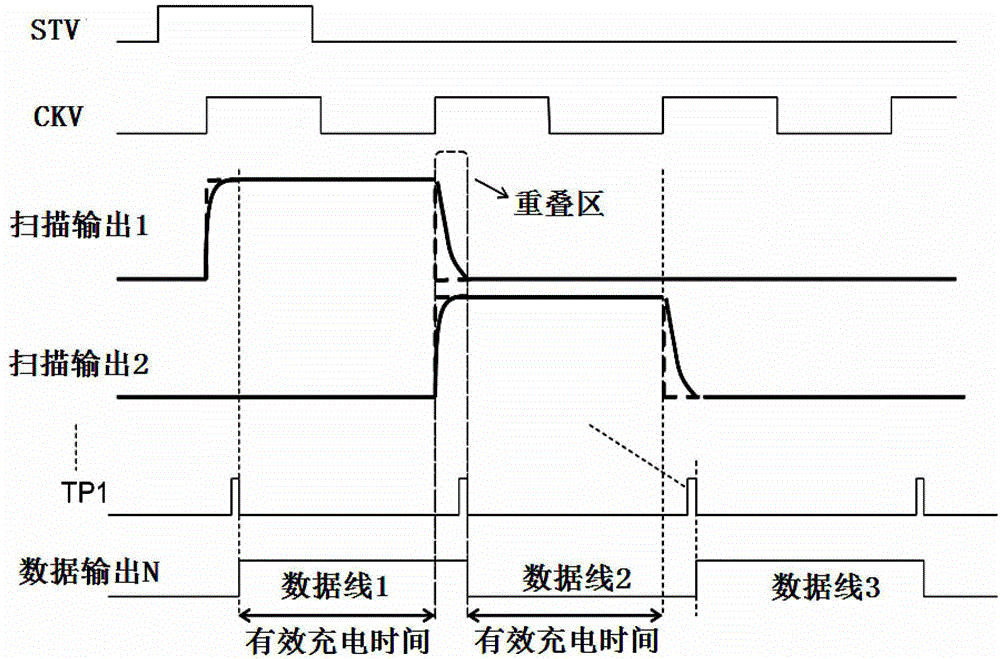

[0049] The sum of the delay time of the timing module and the duration of the data start signal is equal to the time of the overlapping area; the data start chip outputs the data line driving signal at the falling edge of the data start signal. This implementation mode is a technical solution for data output triggered by falling edges, which can ensure that the data is output just after passing the overlapping area, so that the duration of the data signal can be guaranteed to the maximum extent on the premise of avoiding data overlapping in the overlapping area , so that the liquid crystal molecules can have more time to deflect and maintain the corresponding angle to ensure the quality of the display.

example 2

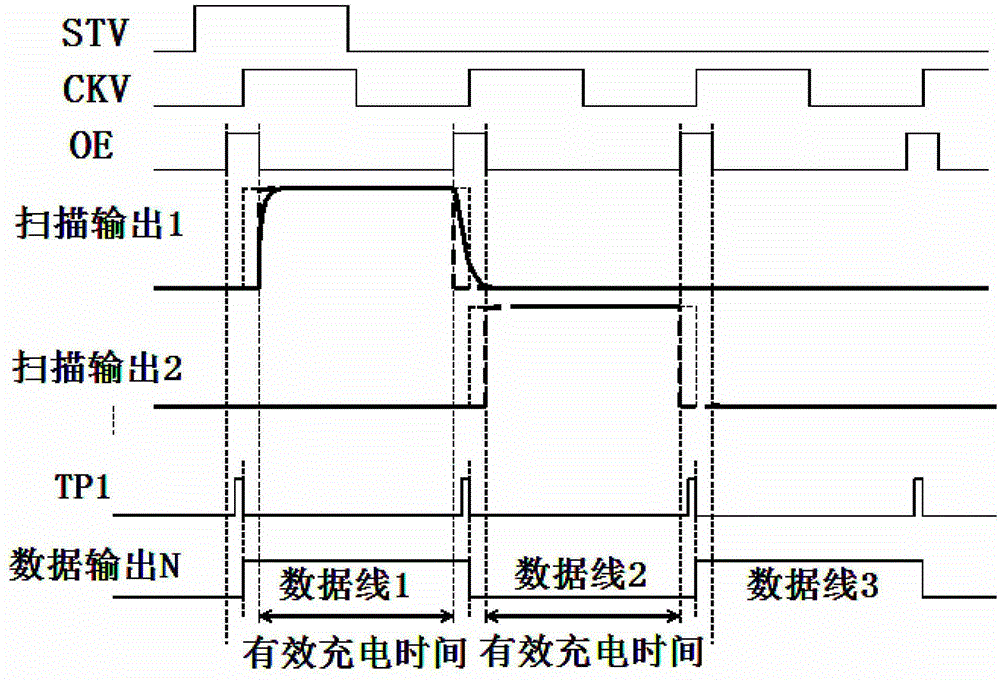

[0051] The delay time of the timing module is not less than the time of the overlapping area; the data start chip outputs the data line driving signal at the rising edge of the data start signal. This implementation mode is a technical solution for triggering data output by a rising edge, which can ensure that the data is output just after passing the overlapping area, so that the duration of the data signal can be guaranteed to the maximum extent on the premise of avoiding data overlapping in the overlapping area , so that the liquid crystal molecules can have more time to deflect and maintain the corresponding angle to ensure the quality of the display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com