Detection device and detection method for internal defects of silicon wafer

A detection device and internal defect technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of shortened service life, waste, and loss of solar cells, and achieve comfortable and convenient operation, convenient silicon wafers, and reduced losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical characteristics of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

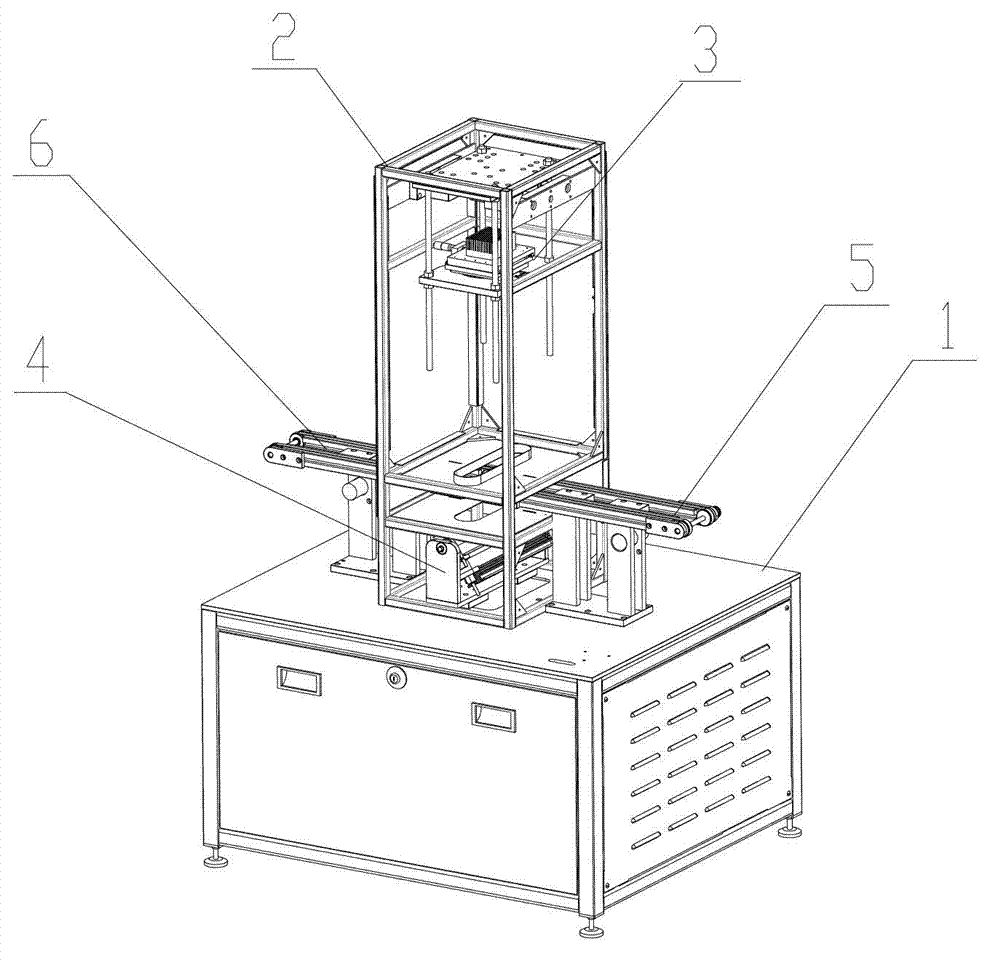

[0024] Such as figure 1 The device for detecting internal defects of a silicon wafer includes a detection module casing 1 forming a darkroom, the front of the detection module casing 1 is an operation table, and a test frame 2 is arranged on the detection module casing 1; The three-dimensional space adjustment of up and down, left and right, front and rear and rotation angle, and the detector adjustment module 3 fixed on the upper part of the test frame; it has the three-dimensional space adjustment of up and down, left and right, front and back and rotation angle of the line light source, and is fixed on the test frame. The lower linear light source adjustment module 4; and the loading conveyor platform 5 and the unloading conveyor platform 7 fixed on the detection module shell 1 through brackets; and necessar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com