Micro-particle weighing sensor of V-shaped folding cantilever beam structure

A weighing sensor and cantilever beam technology, which is applied in the field of micro-particle weighing sensors, can solve the problems of large errors, achieve high sensitivity, high measurement accuracy, and reduce the uncertainty of the measured object.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

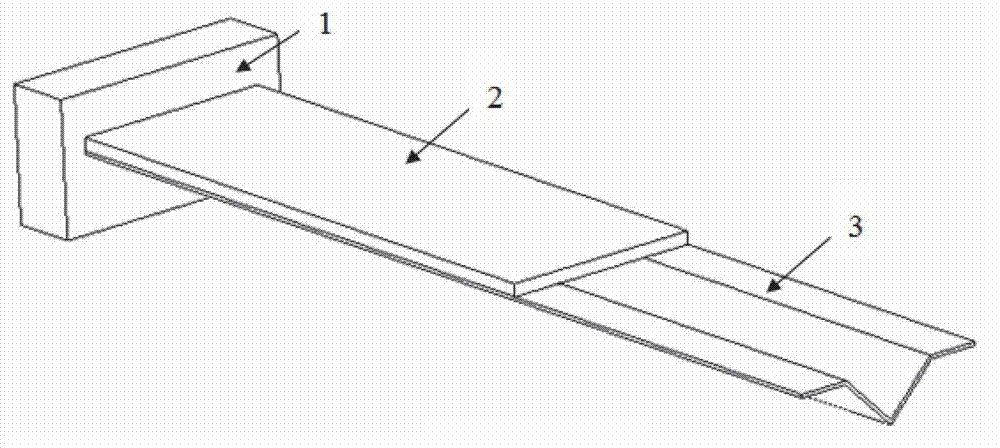

[0039] figure 1 A schematic diagram of the structure of a microparticle load cell with a V-shaped folded cantilever beam structure is given. Wherein, the lower surface of the piezoelectric film 2 is connected to the upper surface of the V-shaped folded cantilever beam 3, and one section of the piezoelectric film 2 and the folded beam is connected to the fixed block 1, and the other end is suspended to form a composite cantilever beam structure. There is no gap connection between the piezoelectric film 2 and the V-shaped folded cantilever beam, and the length of the piezoelectric film 2 is smaller than that of the folded cantilever beam 3 . Bounded by the free end of the piezoelectric film 2, the composite cantilever beam structure is divided into two parts: the composite layer and the extension layer. The folding cantilever beam 3 is a high elastic material.

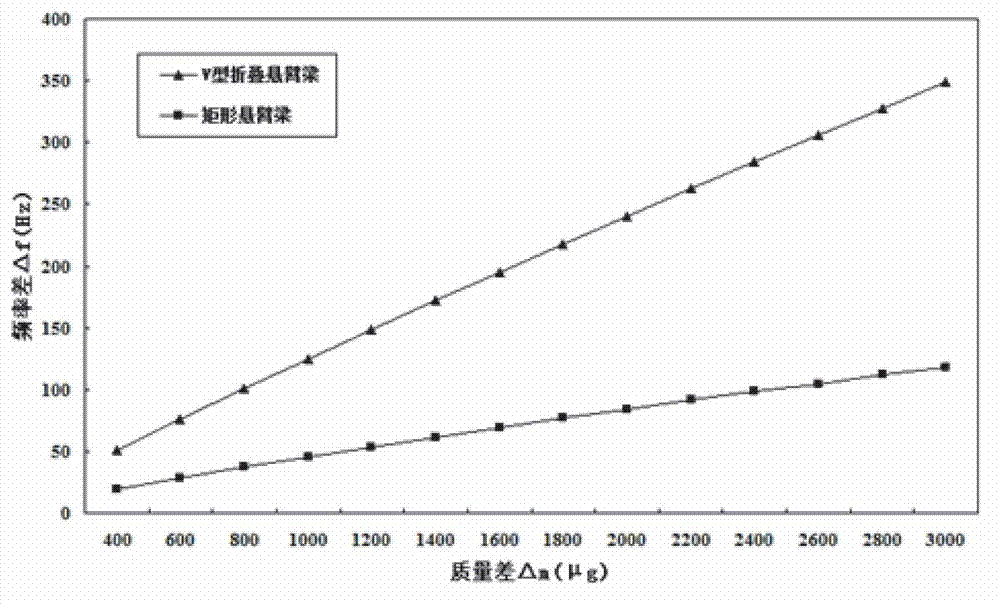

[0040] Calculation example 1: Under the same geometric parameters (as shown in Table 1), the sensitivity comparison ...

Embodiment 2

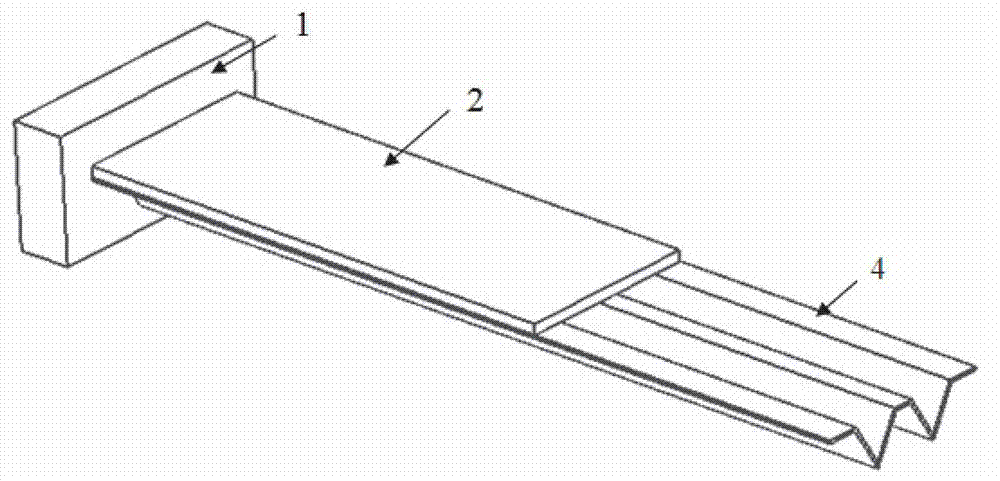

[0044] image 3 It is a structural schematic diagram of Embodiment 2 of a microparticle load cell with a V-shaped folded cantilever beam structure in the present invention. On the basis of Embodiment 1, the folded cantilever beam with a single V-shaped groove is replaced by a folded cantilever beam with multiple V-shaped grooves in succession, which can be used for continuous measurement of various substances.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com