Refrigerator

A refrigerator and heating mechanism technology, applied in the field of defrosting operation of refrigerators, can solve the problems of long defrosting, longer defrosting time, not necessarily promoting heat transfer, etc., to reduce power consumption and defrosting time, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

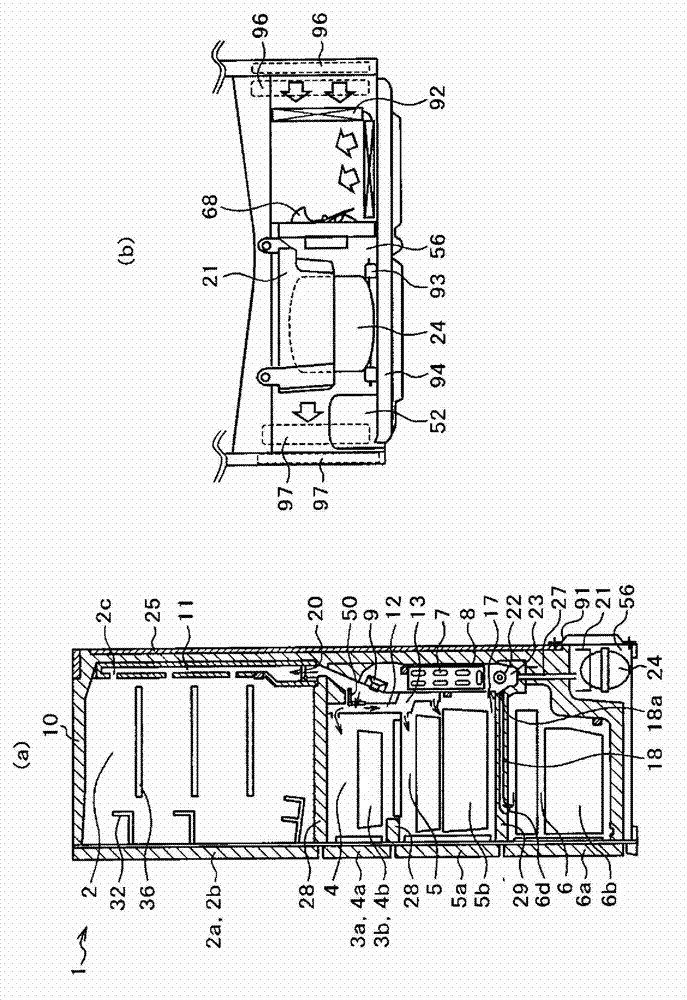

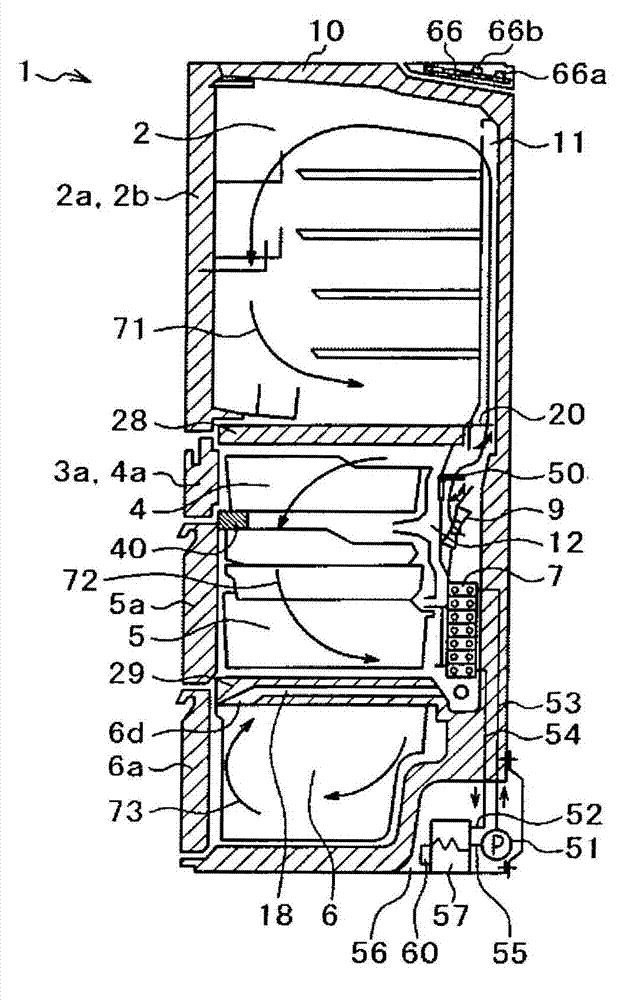

[0037] First, the main features of the refrigerator of the present invention will be described. The refrigerator 1 of the present invention uses the following three heat sources for defrosting. The first is electric energy (defrosting heater), the second is heat energy inside the box, and the third is heat energy outside the box. The defrosting using the first electric energy is heated by an electric heater (for example, a glass tube heater installed at the lower part of the cooler), but the defrosting method is different from the prior art as detailed below. The electric heater heats the air around the cooler, using the air as a medium to indirectly melt the frost. In the second defrosting using heat energy inside the cabinet, the air in the refrigerator compartment (including the vegetable compartment) maintained at a positive temperature zone above freezing is circulated by the fan inside the cabinet, and the frost adhering to the cooler is melted. The so-called internal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com