System and method for recycling and utilizing waste sulfuric acid to produce phosphate and compound fertilizer

A technology of waste sulfuric acid and acid feeding, which is applied in the direction of application, fertilization equipment, fertilizer mixture, etc., can solve the problems of ineffective recycling of waste sulfuric acid, and achieve the effect of saving enterprise cost resources and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and specific embodiments.

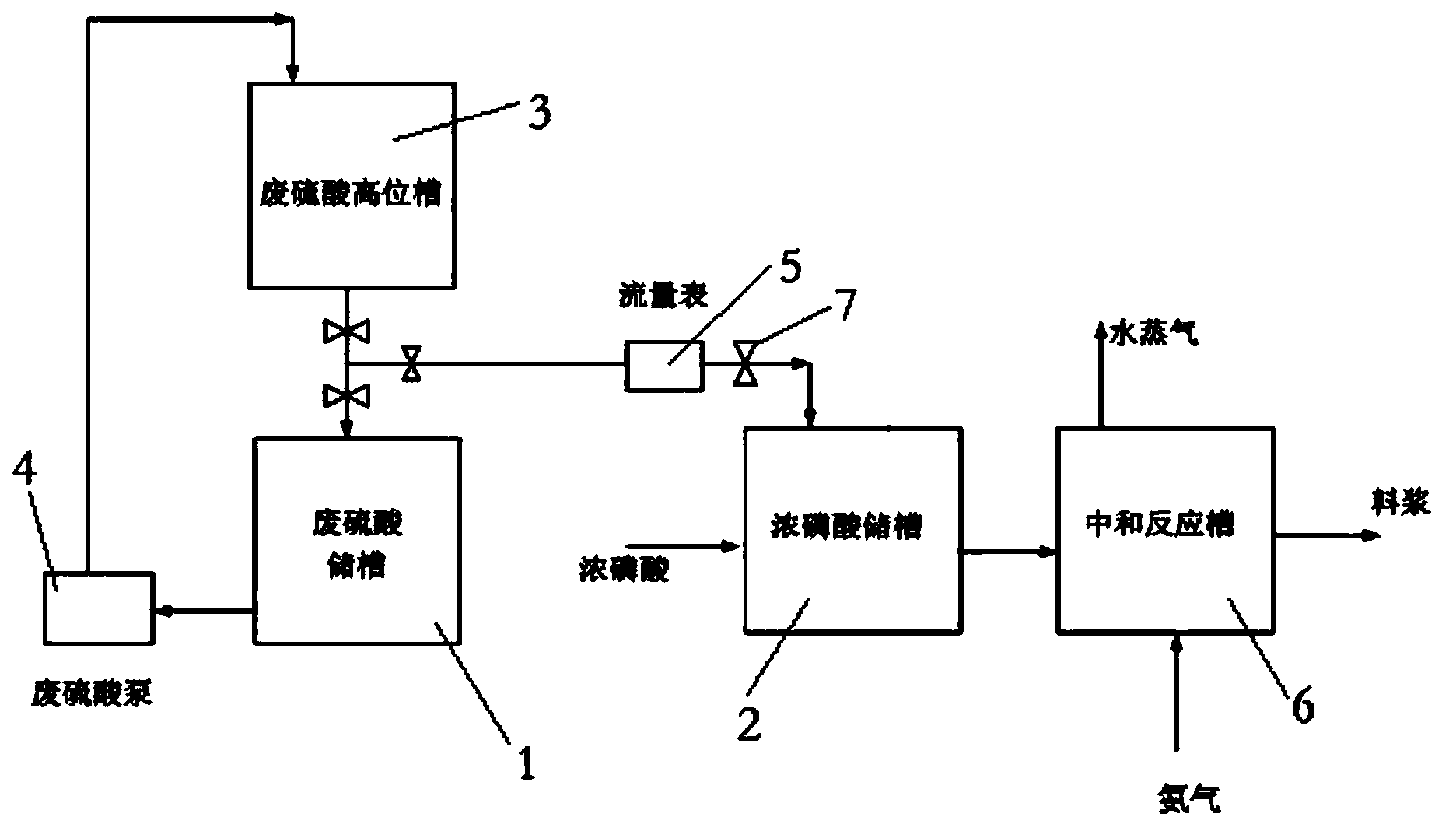

[0015] A kind of waste sulfuric acid recycling system of the present invention produces phosphorus compound fertilizer, and its structure is as follows figure 1 As shown, it includes a waste sulfuric acid storage tank 1, a waste sulfuric acid high-level tank 3, a concentrated phosphoric acid storage tank 2 and a neutralization reaction tank 6; the waste sulfuric acid high-level tank 3 is arranged above the waste sulfuric acid storage tank 1, and the waste sulfuric acid storage tank The acid outlet of the tank 1 is connected with the acid inlet of the waste sulfuric acid high level tank 3 through a pipeline, and a pump 4 is arranged on the pipeline;

[0016] The acid outlet of the waste sulfuric acid head tank 3 is connected with the acid inlet of the concentrated phosphoric acid storage tank 2 through a pipeline, and a flow meter 5 is arranged on the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com