Cinnamon press-packing machine

A press-fitting machine and cassia bark technology, which is applied to presses, material forming presses, manufacturing tools, etc., can solve the problems of low production efficiency and high maintenance cost of cassia bark press-fitting equipment, improve work efficiency, and avoid machine jams and stoppages , The effect of less mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

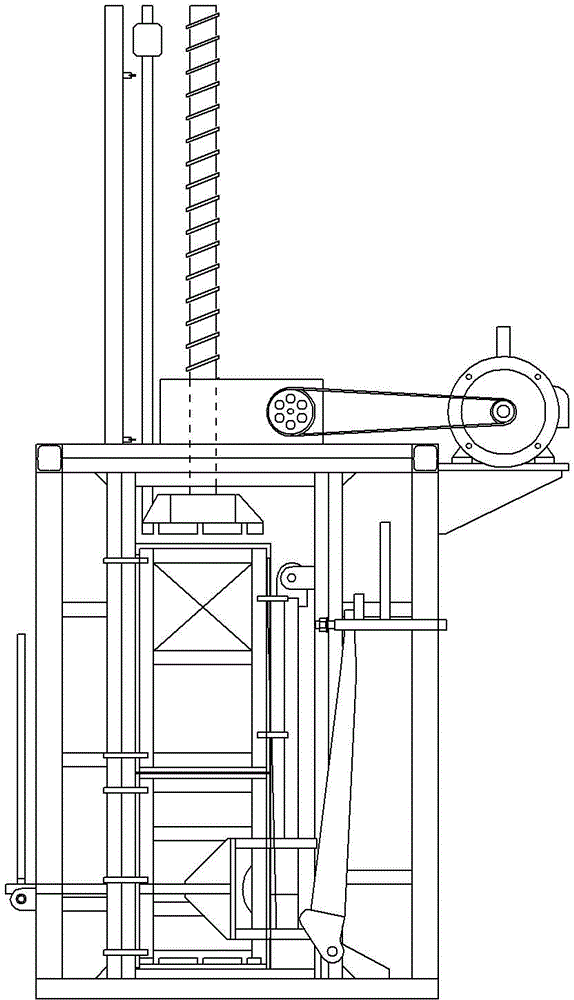

[0017] figure 1 The existing cassia bark pressing machine shown is driven by a motor through a belt transmission system and a gear transmission box to drive the compression screw to drive the pressing head to move up and down, and to press the cassia bark in the pressing basket to complete the production process of the cassia bark bricks;

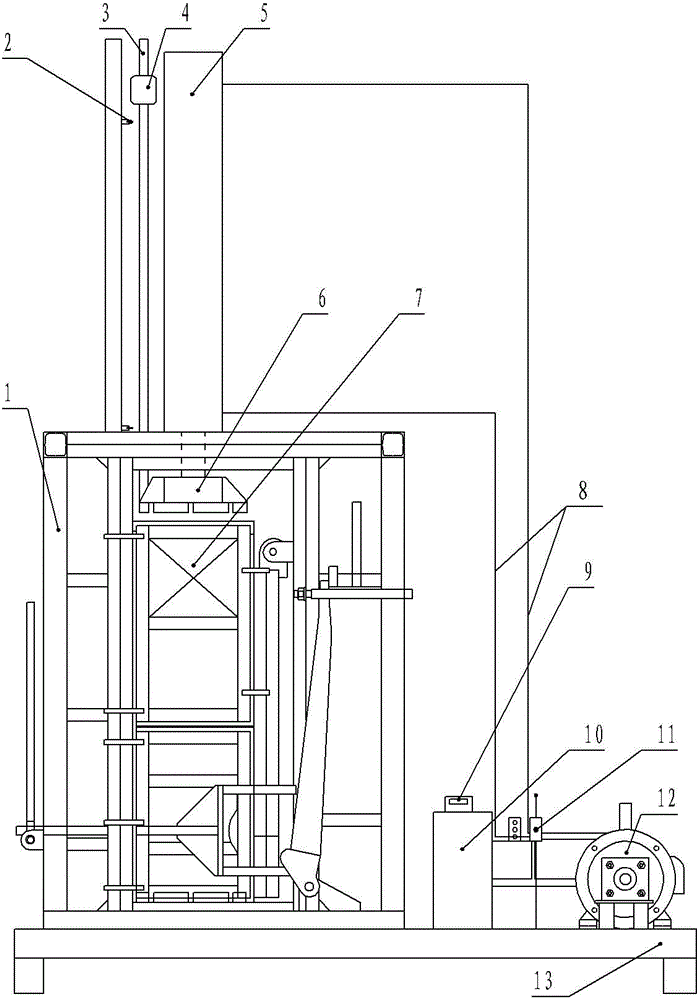

[0018] figure 2 The shown cassia bark pressing machine, compared with the existing cassia bark pressing machine, the transmission of pressure is changed from mechanical drive to hydraulic drive, it includes a frame 1, a pressing basket 7 installed on the frame The pressing head 6 above the basket 7 is connected to the piston rod in the hydraulic drive cylinder 5 fixedly installed on the frame 1, and the hydraulic drive cylinder 5 is connected to the hydraulic station 10 through the oil pipe 8. In the hydraulic oil circuit An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com