A Method for Machining Microstructure Using Non-conductive Plastic as Electrode

A microstructure and electrode processing technology, applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of complex process, high cost, difficult promotion and use, etc., and achieve simple process, short manufacturing cycle, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

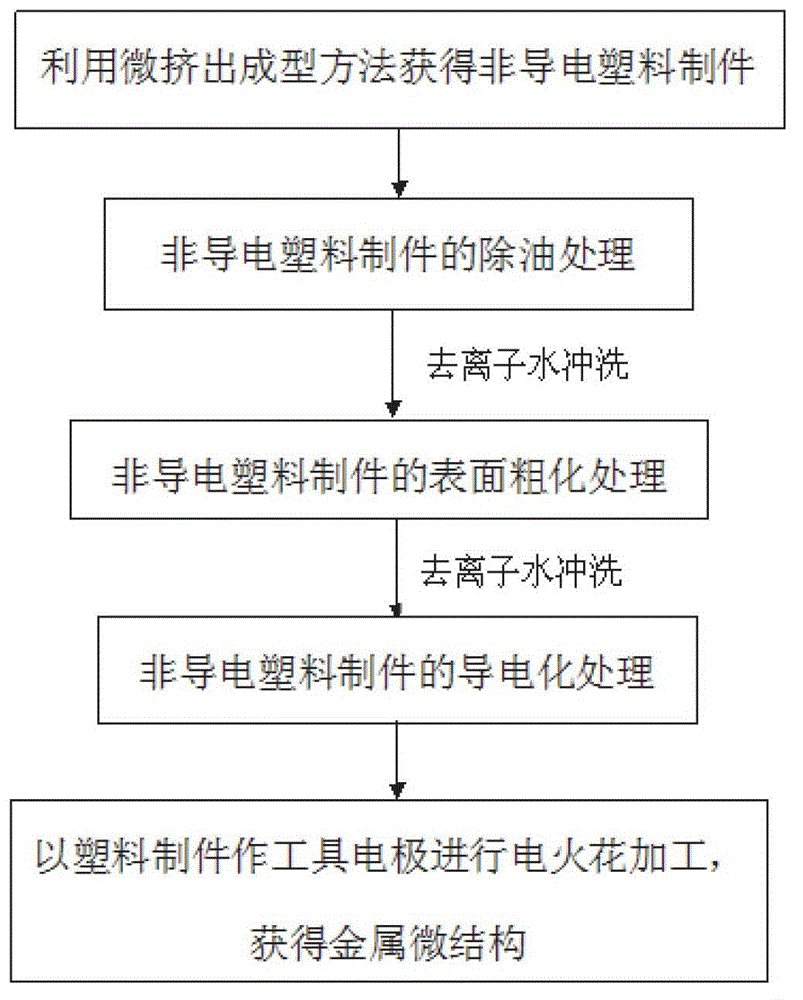

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0027] In the invention, the polypropylene double-cavity micro-tube obtained by micro-extrusion is used as a plastic product, oil removal, surface roughening and conduction treatment are carried out in sequence, and finally the double-cavity micro-tube is used as an electrode for electric discharge machining. Specific steps are as follows:

[0028] (1) Process with a double-cavity microtube mold. First, inject T30S polypropylene raw material particles into the extruder for melting and plasticization. The melting point of polypropylene is 170°C, and the heating temperature of the extruder is 235°C. The plastic melts After entering the micro-extrusion mold for molding, the plastic pipe is introduced into a constant temperature water tank by a tractor at a traction speed of 6m / min for cooling to obtain a polypropylene double-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com