Method for recycling water in laver processing

A technology of seaweed and processing machines, applied in the field of water treatment, can solve problems such as high production costs, high costs, and environmental pollution, and achieve the effects of reducing production water consumption, reducing production costs, and important ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

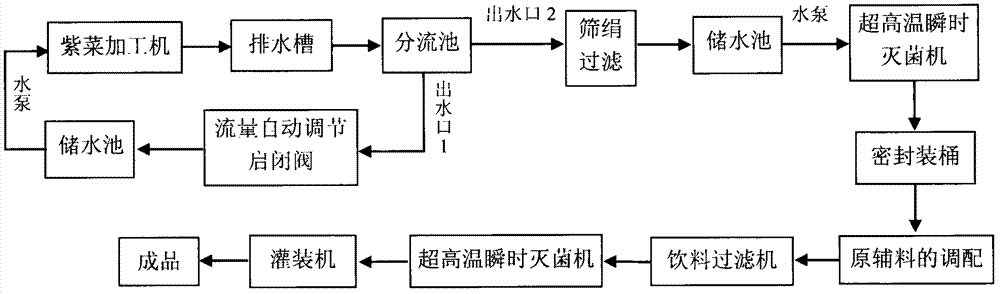

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0010] Disclosed is the recycling of water dehydrated by a seaweed processing machine and a method for producing beverages using circulating water as a raw material. Including the following steps:

[0011] 1. The drainage tank installed on the seaweed processing machine guides the water into the diversion pool for collection and preliminary filtration;

[0012] 2. When the water accumulation in the diversion pool is higher than the water outlet, the flow automatic adjustment opening and closing valve at the water outlet 1 will open, and the water will be pumped to the laver processing machine for recycling;

[0013] 3. When the circulation amount in the above 1 reaches the set amount, the automatic adjustment opening and closing valve of the water outlet 1 is closed, and the water is discharged from the water outlet 2;

[0014] 4. The water d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com