Testing method for shielding effectiveness of small-size shielding cavity

A technology of shielding effectiveness and test method, applied in the direction of measuring electricity, measuring device, measuring electrical variables, etc., can solve the problems of receiving test, large size, and inability to place the antenna inside the cavity, and achieves good versatility, accuracy and Effects with high dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

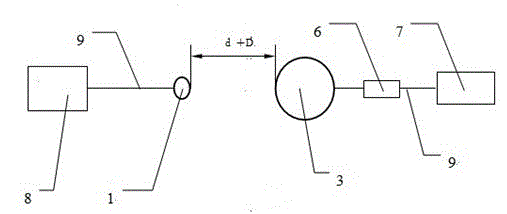

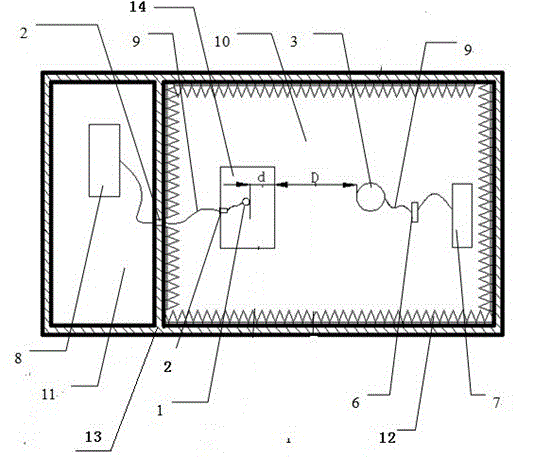

[0028] Such as figure 1 and figure 2 As shown, the semi-anechoic chamber is set up to prevent the incident signal from directly interfering with the receiver, and is an isolation environment adopted to avoid affecting the authenticity of the test.

[0029] The metal wall plate 13 divides the semi-anechoic chamber into two parts, namely the shielded darkroom 10 and the shielded chamber 11 , and the wave-absorbing material 12 is arranged on the wall of the shielded darkroom 10 .

[0030] The wave-absorbing material 12 is a wedge-shaped absorber of polyurethane foam type, non-woven flame-retardant type or silicate plate metal film assembly type.

[0031] The metal wall plate 13 is provided with a two-way radio frequency connector 2, and the two ends of the two-way radio frequency connector 2 are respectively in the shielded dark room 10 and the shielded room 11, and the receiver 8 is placed inside the shielded room 11 alone.

[0032] The two-way radio frequency connector 2 is ...

Embodiment 2

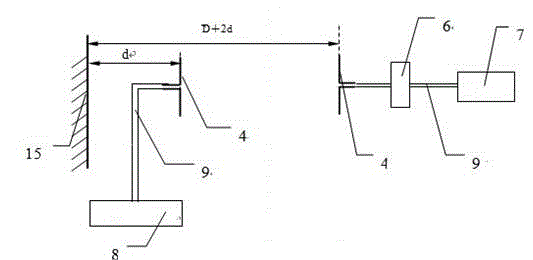

[0047] Such as image 3 and Figure 4 As shown, the equipment setup and test steps of this embodiment are exactly the same as those of Embodiment 1. The difference is that the near-field test antenna 1 and the transmitting antenna 3 use a half-wave vibrator antenna 4, which can perform shielding performance for the electric field frequency band from 100MHz to 1GHz. detection.

Embodiment 3

[0049] Such as Figure 5 and Figure 6 As shown, the equipment setup and test steps of the embodiment are exactly the same as those of the embodiment 1, the difference is that the near-field test antenna 1 and the transmitting antenna 3 adopt the microwave horn antenna 5, which can detect the shielding effectiveness for the plane wave frequency band from 1 GHz to 40 GHz .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com