Waterpower pressurization blasting method

A hydraulic pressurization and water bag technology, applied in the field of blasting, can solve the problems of complex production process, low production efficiency, dust pollution, etc., achieve the effect of simple process, reduce the generation of blasting dust, and increase the packing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further describe the present invention, a hydraulic pressurized blasting method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

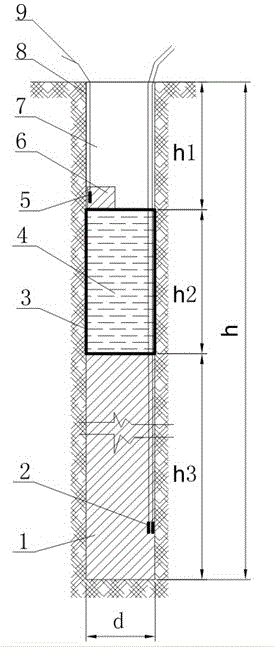

[0026] Depend on figure 1 The shown schematic diagram of the charge structure of a hydraulic pressurized blasting method of the present invention shows that the method of the present invention divides the diameter d and depth h of the blast hole 8 into three parts, upper, middle and lower, and sequentially from top to bottom It is the height h1 of the rock cuttings 7, the height h2 of the water column 4 and the charge height h3 of the main explosive 1.

[0027] Among them: h=h1+h2+h3≈12m, d=200mm~250mm, h2=2.5~4m, h1=(12~20)d.

[0028] A kind of hydraulic pressurized blasting method of the present invention is carried out according to the following technological process:

[0029] 1) The main explosive 1 is loaded into the lower part of the continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com