Automatic forming packaging machine for candy fireworks

A technology for automatic molding and candy fireworks, which is applied in pyrotechnics, weapon types, offensive equipment, etc. It can solve the problems of not being suitable for mass production and market discharge requirements, difficult to guarantee quality, and high labor intensity, etc., to achieve a simple and compact structure of the whole machine , improve work efficiency, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

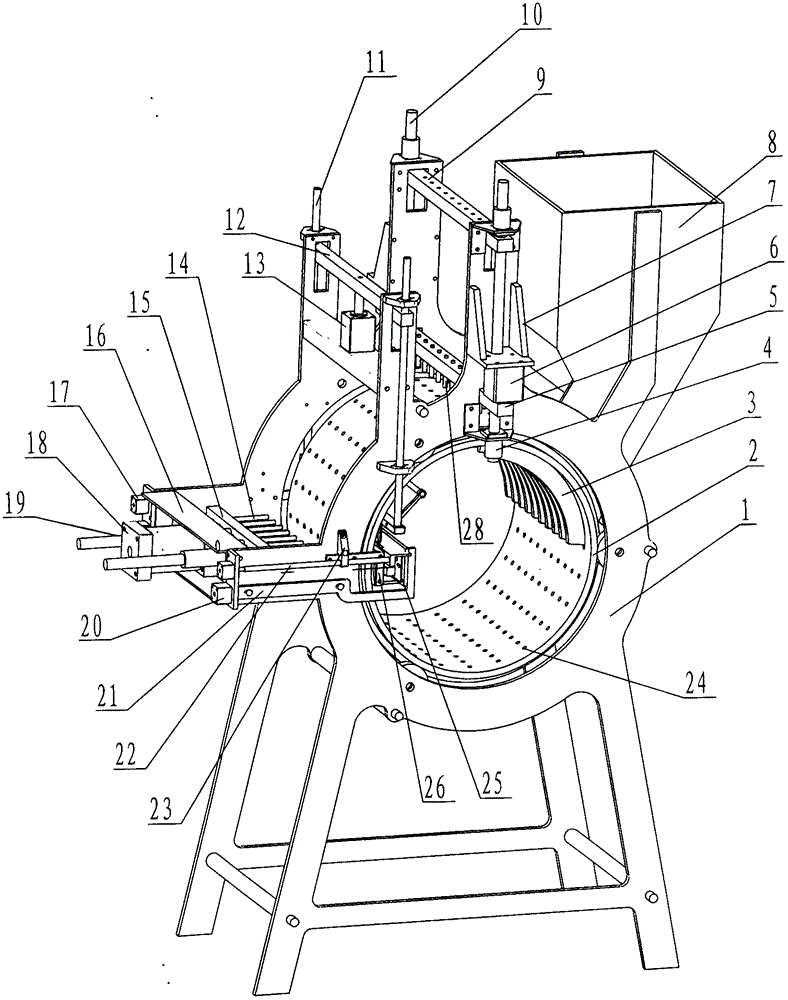

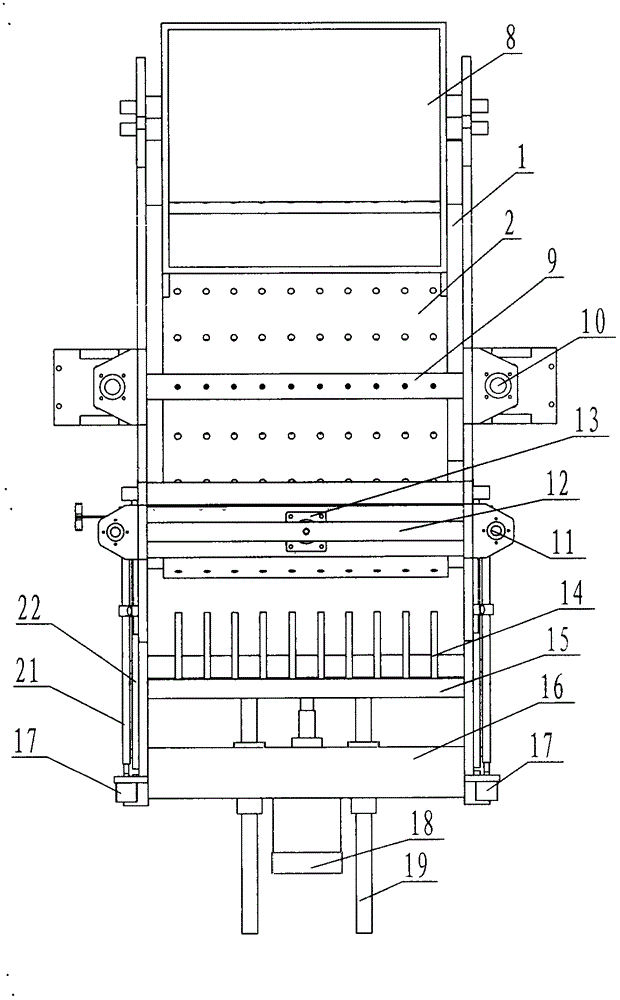

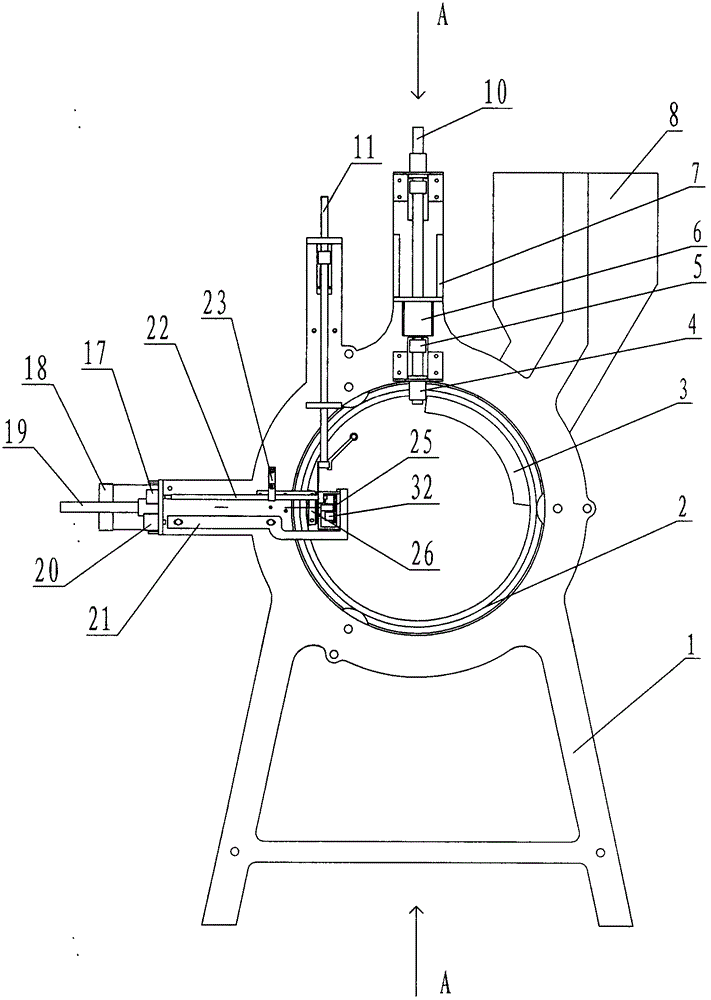

[0026] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments:

[0027] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 An embodiment of the invention is shown. Its composition is mainly composed of frame 1, grain forming drum 2, supporting knife plate 3, linear bearing 4, pressure grain cross arm 5, inserting and pressing die driving cylinder 6, cylinder seat 7, lower hopper 8, guide Cross arm 9, linear shaft 10, film feeding guide shaft 11, cylinder driven cross arm 12, film feeding cylinder 13, grain push pin 14, grain push pin fixed beam 15, cylinder fixing seat 16, film pressing cylinder 17 , Grain push needle cylinder 18, linear shaft 19, film cutting cylinder 20, film cutting connecting rod 21, film pressing connecting rod 22, film positioning seat 23, medicine column mold hole 24, locking device 25, forming plate 26 , The keyhole 27, the punching pin 28, the film pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com