Icebreaking roller

An ice-breaking roller and roller frame technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of difficult and complex road conditions, excessive motor load, inconvenient frequency adjustment, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

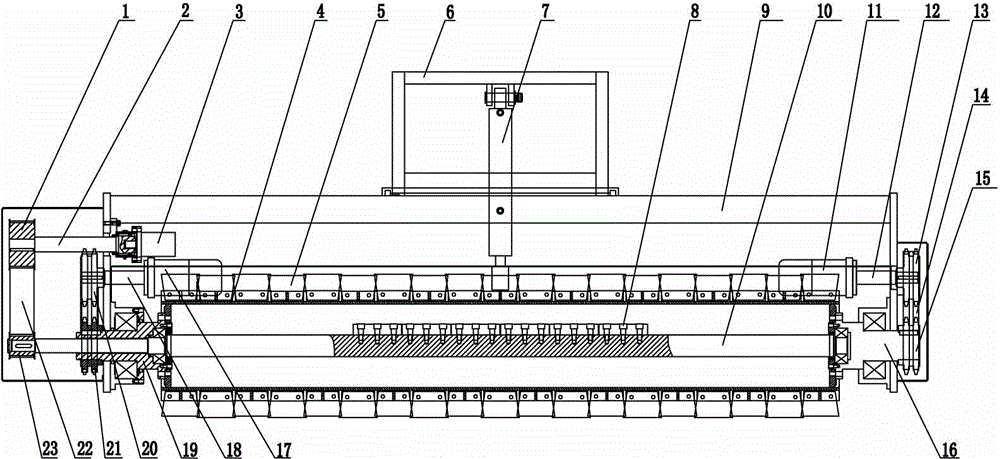

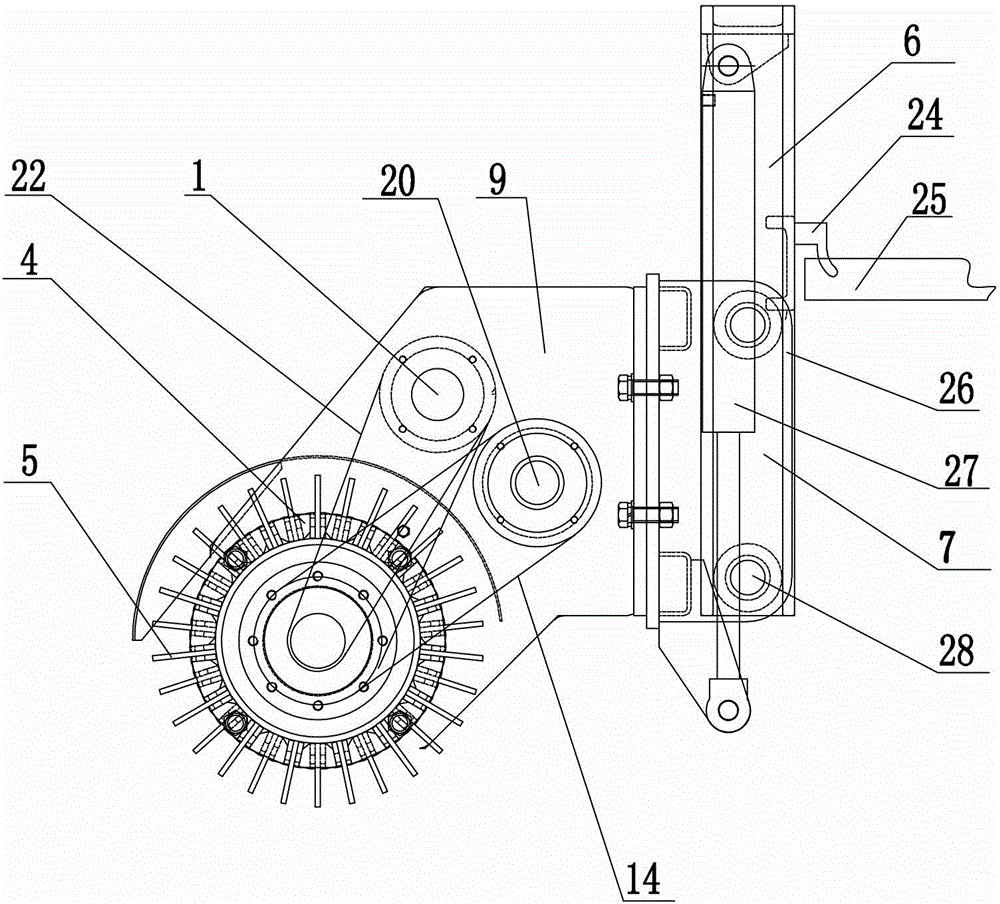

[0025] Such as figure 1 , 2 As shown, a kind of ice-breaking roller comprises the connecting frame 25 on the ice-breaking motor vehicle, the roller frame 9, the rolling device connected in rotation with this roller frame 9, the vibrating device located in this rolling device, and the described rolling device includes a surface The ice-breaking roller body 4 provided with the cutting edge 5, the rotating sleeve 19 fixedly connected with one end of the ice-breaking roller body 4, the connection short shaft 16 fixedly connected with the other end of the ice-breaking roller body 4, the rotation The sleeve 19 and the connecting short shaft 16 are respectively rotatably connected with the roller frame 9, and the vibration device includes a main vibration shaft 10 with a set of eccentric blocks 8 in the middle,

[0026] It is characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com