Treatment device and recovering method for pressing alkali

A technology of alkali treatment and lye, which is applied in separation methods, rayon recovery, chemical instruments and methods, etc. It can solve the problems of low efficiency of alkali recovery in dialysis process, large water consumption, high investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

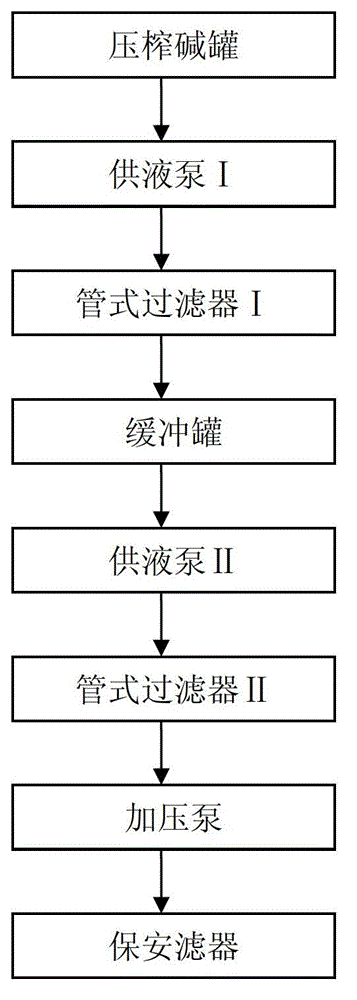

[0013] Such as figure 1 As shown, the specific embodiment of the present invention mainly includes the following steps: the squeezed alkali is injected into the tubular filter I through the liquid supply pump I, and the semi-fibers above 20 to 35 microns are separated. Type filter II further separates the semi-fiber impurities above 10 microns, and passes through the security filter after being pressurized by the booster pump to remove semi-fibers above 5 microns. The treatment efficiency of the whole set of devices above 5 microns can reach more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com