Ketone-benzene dewaxing apparatus capable of reducing deoiling fresh solvent

A ketone-benzene dewaxing and deoiling technology, which is applied to the recovery of petroleum wax, can solve the problems of high energy consumption in the fresh solvent production process, large load of the wax oil recovery system, and increased energy consumption of the wax oil recovery. Reduce the fresh solvent ratio, ensure material balance, and reduce the load on the recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

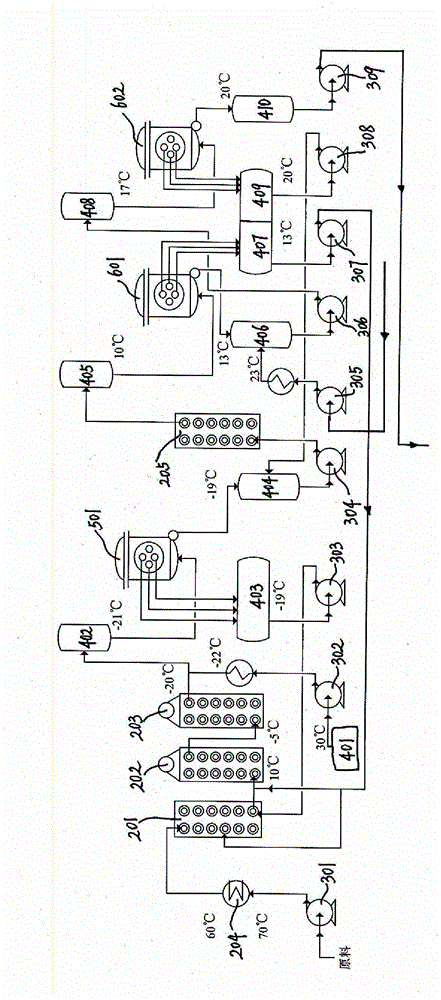

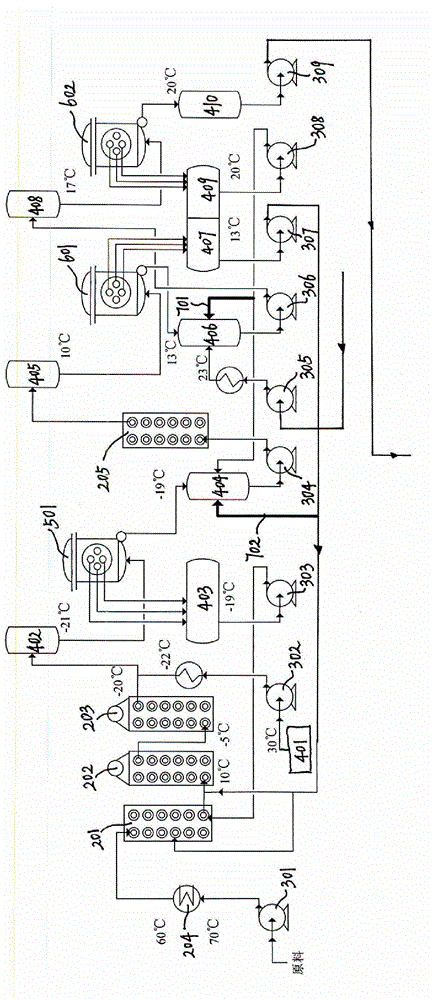

[0049] Such as figure 2 A ketone-benzene dewaxing device that can reduce fresh solvent for deoiling is shown, the ketone-benzene dewaxing device includes a heat exchange unit, a dewaxing unit, a primary deoiling unit and a secondary deoiling unit connected in sequence, and the heat exchange unit Including the first heat exchanger 201, the second heat exchanger 202 and the third heat exchanger 203 connected in series in sequence, the raw oil is pumped into the first heat exchanger 201; the dewaxing unit includes a dewaxing filter 501, a dewaxing filtrate container 403 , the dewaxing wax paste container 404, a mixing container 402 is also arranged between the third heat exchanger 203 and the inlet end of the dewaxing filter 501, and the outlet end of the dewaxing filter 501 is respectively connected with the dewaxing filtrate container 403, the dewaxing filter The wax paste container 404 is connected, and the raw oil enters the mixing container 402 after being cooled by the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com