Hydrogenation heat gas chemical yield increasing solution component for low-permeability sandstone reservoir oil well

A chemical stimulation and low permeability technology, applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

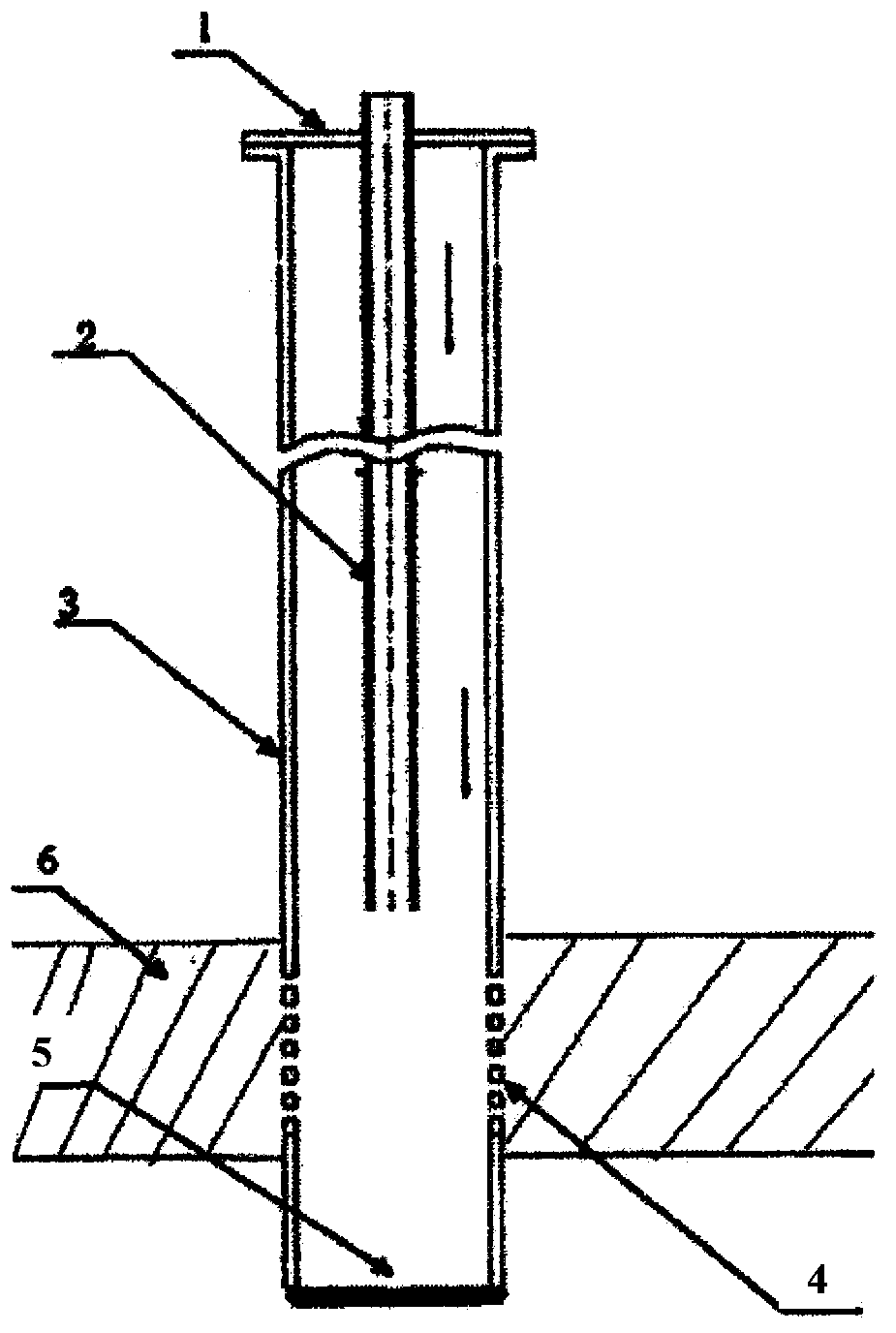

Image

Examples

Embodiment 1

[0038] Example 1: Hydrogenation Hot Gas Chemical Stimulation Test of No. 1 Oil Well in Daqing Oilfield

[0039] Geological conditions and related parameters of oil well No. 1: reservoir series sandstone and siltstone; medium-porosity and low-permeability oil layers; inner diameter of casing 121.36mm, artificial well bottom 1428.3m; perforation range 1338.2 ~ 1367.5m; daily fluid production before stimulation operation was 2.5t, of which daily oil production was 2.0t; from the above data it can be concluded that the volume of the reaction zone is 1045L. Prepare No. 1 solution 650kg, No. 2 solution 650kg.

[0040] The ingredients of solution No. 1 include: ethanolamine nitrate complex HOCH 2 CH 2 NH 2 ·HNO 3 , ammonium nitrate NH 4 NO 3 , water H 2 O, the respective mass percentages: 30%, 48.5%, 21.5%. The mass of each component is respectively: 195kg of nitroethanolamine complex, 315.25kg of ammonium nitrate, and 139.75kg of water.

[0041] Components of solution No. ...

Embodiment 2

[0044] Example 2: Hydrogenation Hot Gas Chemical Stimulation Test of No. 2 Oil Well in Daqing Oilfield

[0045] Geological conditions and related parameters of oil well No. 2: reservoir series sandstone and siltstone; medium-porosity and low-permeability oil layers; inner diameter of casing 121.36mm, artificial well bottom 1380.6m; perforation range 1293.0-1320.2m; daily fluid production before stimulation operation 3.0t, of which daily oil production is 2.5t; from the above data, the volume of the reaction zone is 1016.2L. Prepare No. 1 solution 650kg, No. 2 solution 650kg.

[0046] The ingredients of solution No. 1 include: ethanolamine nitrate complex HOCH 2 CH 2 NH 2 ·HNO 3 , ammonium nitrate NH 4 NO 3 , water H 2 O, the respective mass percentages: 40%, 45.3%, 14.7%. The mass of each component is respectively: 260 kg of ethanolamine nitrate complex, 294.45 kg of ammonium nitrate, and 95.55 kg of water.

[0047] Components of solution No. 2 include: hydrazine nit...

Embodiment 3

[0050] Example 3: Hydrogenation hot gas chemical stimulation test of No. 3 oil well in Daqing Oilfield

[0051] Geological conditions and related parameters of oil well No. 3: reservoir series sandstone and siltstone; medium-porosity and low-permeability oil layers; inner diameter of casing 121.36mm, artificial well bottom 1217.6m; perforation range 1145.3 ~ 1176.0m; the well was abandoned before the stimulation operation, with a daily oil production of 0t; from the above data, the volume of the reaction zone is 839L. Prepare No. 1 solution 520kg, No. 2 solution 520kg.

[0052] The ingredients of solution No. 1 include: ethanolamine nitrate complex HOCH 2 CH 2 NH 2 ·HNO 3 , ammonium nitrate NH 4 NO 3 , water H 2 O, the respective mass percentages: 35%, 54.6%, 10.4%. The masses of each component are: 182kg of ethanolamine nitrate complex, 283.92kg of ammonium nitrate, and 54.08kg of water.

[0053] Components of solution No. 2 include: hydrazine nitrate N 2 h 4 ·HNO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com