Environment-friendly energy-saving greenhouse

An environmentally friendly and energy-saving greenhouse technology, applied in the field of greenhouses, can solve the problems of overheating, lower power generation efficiency, and high installation location, and achieve the effects of reducing heat loss to the external environment, ensuring respiration, and high-efficiency photovoltaic power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

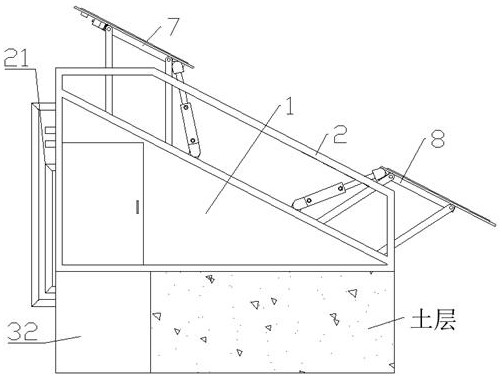

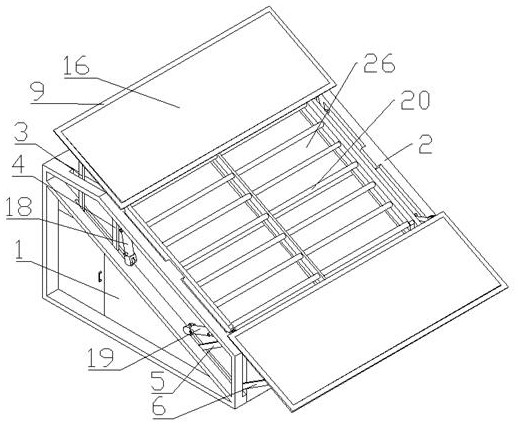

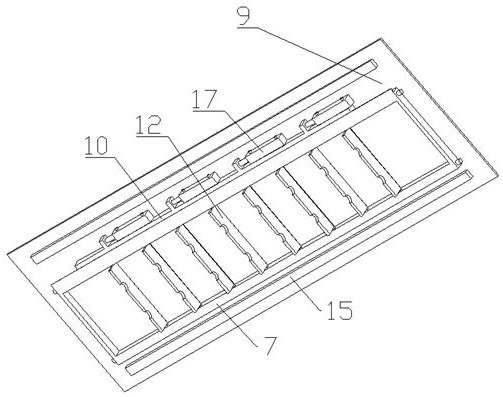

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as Figure 1-6 As shown, an environmentally friendly and energy-saving greenhouse, including a wall 1, a support frame 2, a No. 1 swing rod 3, a No. 2 swing rod 4, a No. 3 swing rod 5, a No. 4 swing rod 6, an upper mounting frame 7, and a lower mounting frame 8. Heat conduction plate 9, rack frame 10, support shaft 11, heat dissipation plate 12, gear 13, arc groove 14, fill light belt 15, photovoltaic panel 16, No. 1 linear cylinder 17, No. 2 linear cylinder 18, three No. linear cylinder 19, heat exchange part 20, ventilation part 21, the front and rear ends of the wall 1 are respectively fixed with a support frame 2, and the two support frames 2 are sequentially hinged with a No. 1 swing rod 3 and No. 2 Swing rod 4, No. 3 swing rod 5 and No. 4 swing rod 6, the upper mounting bracket 7 is jointly hinged between the two described N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com