Full-automatic oil separation lifting integrated device

A fully automatic, oil-separating technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Problems such as poor oil separation effect and poor sealing performance of oil separation pools can save civil construction investment costs, avoid waste in subsequent treatment, and facilitate rapid separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

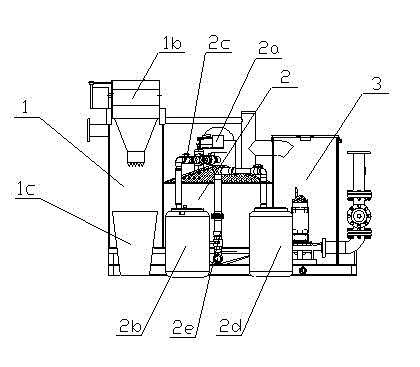

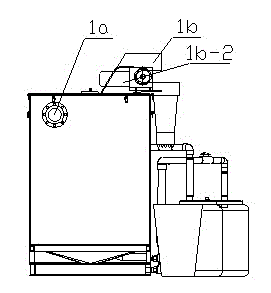

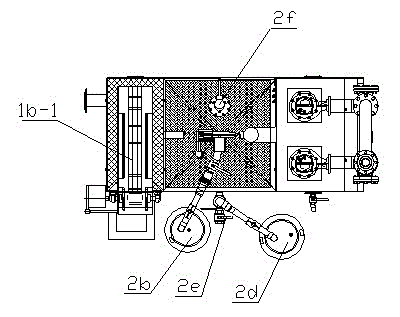

[0033] see Figure 1 to Figure 3 , a fully automatic oil-separating and lifting integrated equipment provided by the present invention, comprising a connected debris separation box 1, an oil-water separation box 2 and a sewage lifting box 3, one side of the debris separation box 1 passes through the water inlet assembly 1a is connected to the waste water inlet pipeline, and the water inlet in the debris separation box 1 is provided with a mechanical grille 1b, see figure 2 , image 3 , the mechanical grille 1b is composed of an inclined conveyor belt 1b-1 inserted obliquely into the debris separation box 1, and a motor 1b-2 that provides power for the conveyor belt. The outer surface of the inclined conveyor belt 1b-1 Several groups of drag hooks are evenly distributed, and the insertion end of the inclined conveyor belt 1b-1 is in contact with the inner wall of the debris separation box 1. After the waste water enters, the motor 1b-2 drives the inclined conveyor belt 1b-1 t...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that in order to prevent the oil in the oil-water separation box 2 from solidifying and cannot be discharged, a heating device 2f is arranged on the oil-water separation box 2 to heat the oil that may solidify. The heating device 2f includes an electric heating rod installed in the oil-water separation tank 2 and a heating blanket laid on the body of the oil-water separation tank 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com