Planetary motion grinding device

A grinding device, motion-type technology, applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problem of reducing the stability of revolution motion and system dynamic stiffness, reducing the sensitivity of axial reciprocating motion of the rotation axis, and reducing the stability of the removal function And other problems, to achieve the effect of improving rotational symmetry, improving motion sensitivity, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

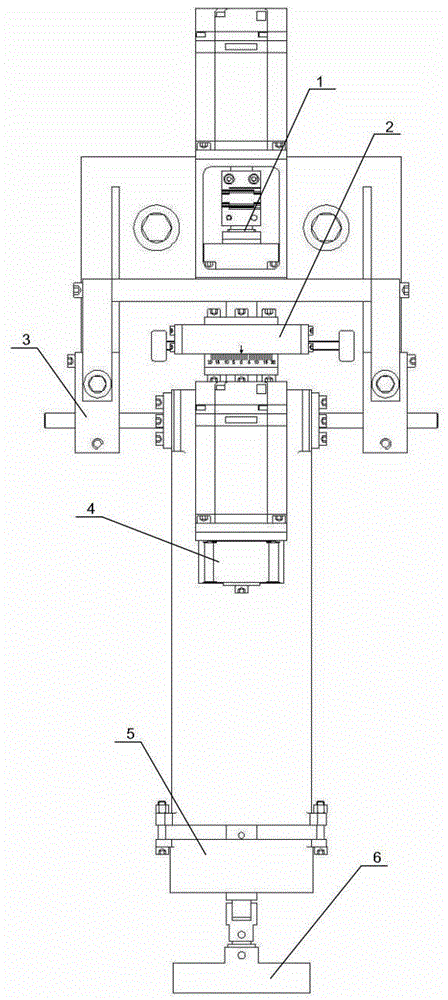

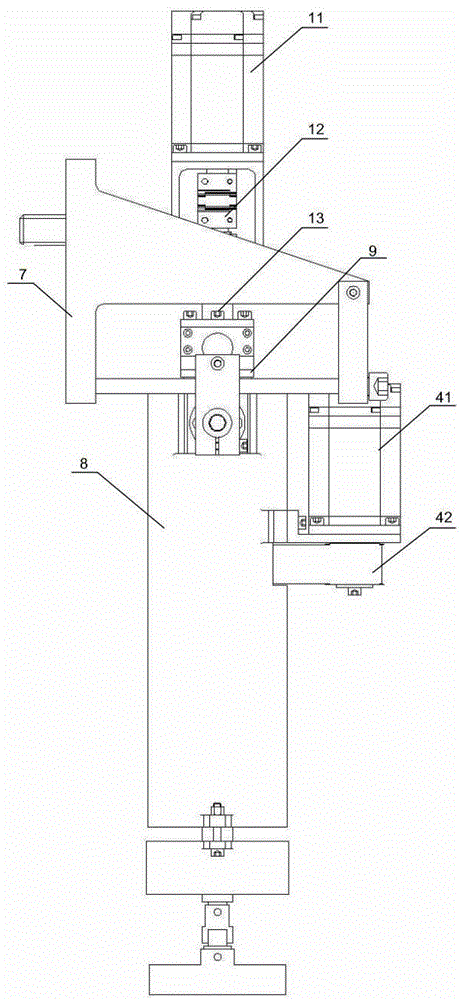

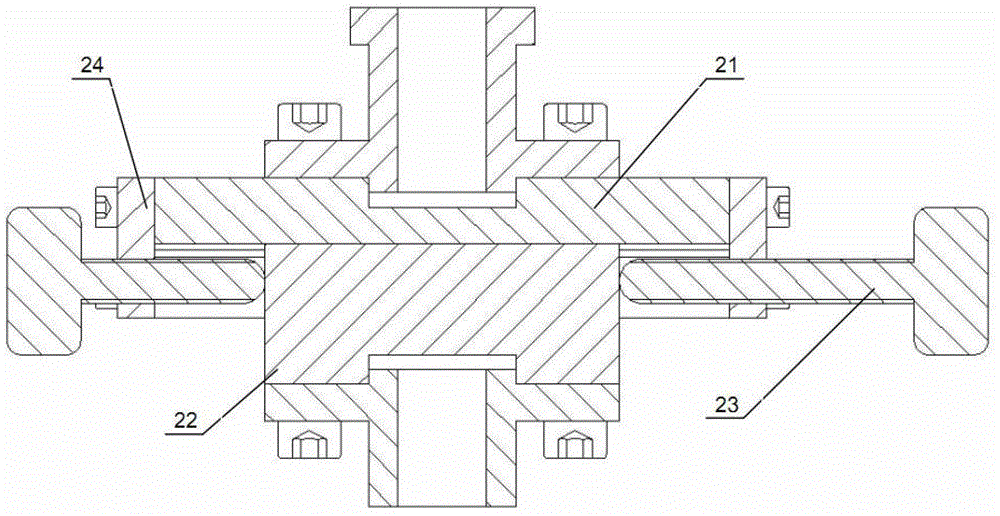

[0025] Such as Figures 1 to 9 As shown, a planetary motion grinding device of the present invention includes a revolution mechanism 1, an eccentric adjustment mechanism 2, a translation holding mechanism 3, an autorotation mechanism 4, a pressure applying mechanism 5, a grinding disc mechanism 6, an interface panel 7, and a main seat Body 8, rotary mechanism 9. The revolution mechanism 1 is connected to the interface panel 7, the eccentric adjustment mechanism 2 is connected to the lower end of the revolution mechanism 1, and the flange of the revolution shaft system 13, and the translation holding mechanism 3 is located outside the eccentric adjustment mechanism 2, and is connected to the interface panel 7 and the main body 8, the rotary mechanism 9 is connected to the lower end of the eccentric adjustment mechanism 2, on the lower dovetail 22, located in the main base body 8, the autorotation mechanism 4 is located below the rotary mechanism 9, connected to the main base bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com