Device capable of remotely controlling flow direction of materials

A remote control and material technology, applied in the direction of centrifuges, etc., can solve the problems of inaccessibility of operators for maintenance, high matching precision, sensitive material and liquid slag content, etc., to improve life, ensure no leakage, and ensure flexibility and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

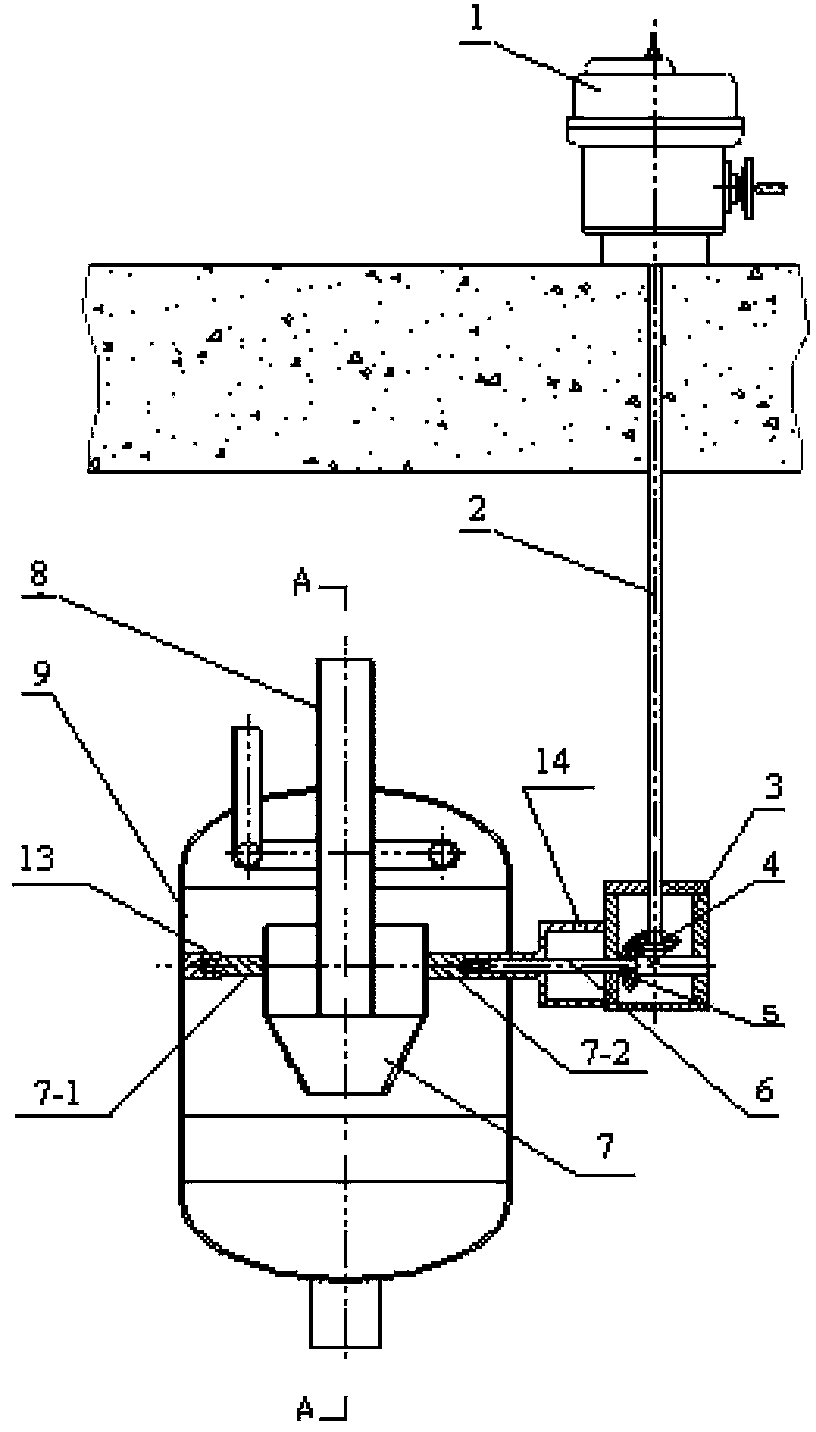

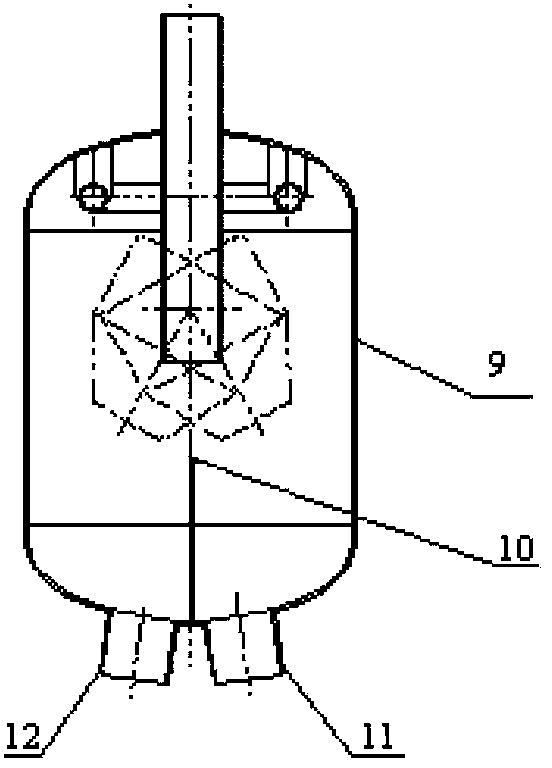

[0020] Such as figure 1 As shown, the device provided by the present invention can remotely control the flow direction of materials, including a receiving tank 9 and a feeding pipe 8 arranged on the top of the receiving tank 9, and the center of the receiving tank 9 is provided with a cone 7 penetrating up and down. (The tapered mouth of the cone 7 faces downward), the delivery pipe 8 extends into the cone 7; the outside of the receiving tank 9 is provided with a control assembly, which includes the electric drive 1 and the electric drive through the first transmission shaft 2 1 connected bevel gear set, the bevel gear set is connected with the cone cylinder 7 through the second transmission shaft 6 extending into the receiving tank 9, and drives the second transmission shaft 6 to drive the cone cylinder 7 to rotate around the axis where the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com