A kind of preparation method and application of modified tobacco powder slurry

A tobacco powder and modification technology, which is applied in the field of modified tobacco powder pulp and its preparation, can solve the problems of poor retention and drainage effects, unavailability of waste tobacco powder reuse, large amount of guar gum additives, etc. problem, to achieve the effects of increased flue gas richness, good loss, and small amount of miscellaneous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

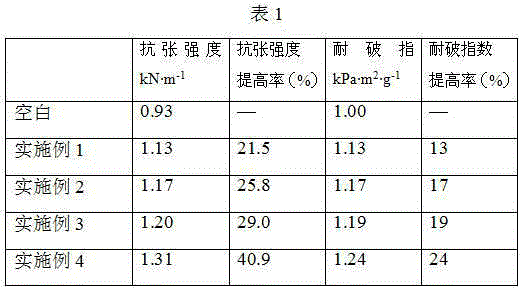

Examples

Embodiment 1

[0033] (1) Dilute the ground tobacco powder slurry with water to make a suspension with a mass percentage of 3%, and stir;

[0034] (2) Slowly add cationic guar gum with a molecular weight of 300,000 (purchased from Danisco, or other commercially available cationic guar gum) into water under stirring conditions, and prepare cationic guar gum to account for the mass of the solution. The percentage of the solution is 1%, fully stirred for 20 minutes, then heated the solution to 40 ° C, kept stirring for 80 minutes and then set aside;

[0035] (3) adding water to the cationic guar gum solution dissolved in step (2) and diluting it again until the mass percent concentration of the cationic guar gum is 0.1%, to obtain a cationic guar gum solution for modification;

[0036] (4) Add the cationic guar gum solution for modification obtained in step (3) to the tobacco powder suspension prepared in step (1), and the amount added is as follows: the mass percentage concentration of cationi...

Embodiment 2

[0039] (1) Dilute the ground tobacco powder slurry with water to make a suspension with a mass percentage of 6%, and stir;

[0040] (2) Slowly add cationic guar gum with a molecular weight of 200,000 to water under stirring conditions, and prepare a solution in which the cationic guar gum accounts for 3% of the solution mass, stir well for 15 minutes, and then heat the solution to 35°C, heat preservation and stirring for 70 minutes and then set aside;

[0041] (3) adding water to the cationic guar gum solution dissolved in step (2) and diluting it again until the mass percent concentration of the cationic guar gum is 0.3%, to obtain a cationic guar gum solution for modification;

[0042] (4) Add the cationic guar gum solution for modification obtained in step (3) to the suspension of tobacco powder prepared in step (1), and the amount added is as follows: the mass percentage concentration of cationic guar gum relative to the powder pulp is 0.5 %, stirred for 30 minutes, and t...

Embodiment 3

[0045] (1) Dilute the ground tobacco powder slurry with water to make a suspension with a mass percentage of 10%, and stir;

[0046] (2) Slowly add cationic guar gum with a molecular weight of 200,000 to water under stirring conditions, and prepare a solution in which the cationic guar gum accounts for 3% of the solution mass, stir well for 15 minutes, and then heat the solution to 35°C, heat preservation and stirring for 70 minutes and then set aside;

[0047] (3) adding water to the cationic guar gum solution dissolved in step (2) and diluting it again until the mass percent concentration of the cationic guar gum is 0.2%, to obtain a cationic guar gum solution for modification;

[0048](4) Add the cationic guar gum solution for modification obtained in step (3) to the tobacco powder suspension prepared in step (1), and the amount added is as follows: the mass percentage concentration of cationic guar gum relative to the tobacco powder pulp is 0.7 %, stirred for 30 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com